Release time:2025-11-25 popularity:407

Building a modern fertilizer plant requires more than just raw materials and a production site—it demands precision-engineered equipment capable of handling complex chemical reactions safely, efficiently, and reliably. Among all core machinery, Custom Reactor Equipment for Fertilizer Plants plays one of the most decisive roles, as these reactors directly impact reaction quality, product consistency, energy consumption, and long-term operating costs. By investing in high-quality Custom Reactor Equipment for Fertilizer Plants, manufacturers can tailor the reactor design to their specific formulas, production capacity, and process conditions, ensuring maximum efficiency and consistent results.

This guide walks you through how custom reactors function, why they are indispensable in fertilizer manufacturing, and why choosing the right reactor design matters more today than ever before.

Every fertilizer formula behaves differently. Whether you’re producing NPK, SSP, MAP, DAP, or specialty organic–inorganic blends, the reaction conditions—including temperature, pressure, agitation level, corrosion resistance, pH stability, and heat transfer—must precisely match the requirements of the process. This is exactly where Custom Reactor Equipment for Fertilizer Plants becomes critical.

Unlike standard reactors, custom-built units are engineered around your formula, production capacity, temperature curve, and corrosion risks. They ensure stable reaction kinetics, safer chemical handling, higher conversion rates, reduced energy usage, fewer batch inconsistencies, and a longer overall equipment lifespan.

In short, a fertilizer plant’s product quality is only as strong as the reactor supporting the process.

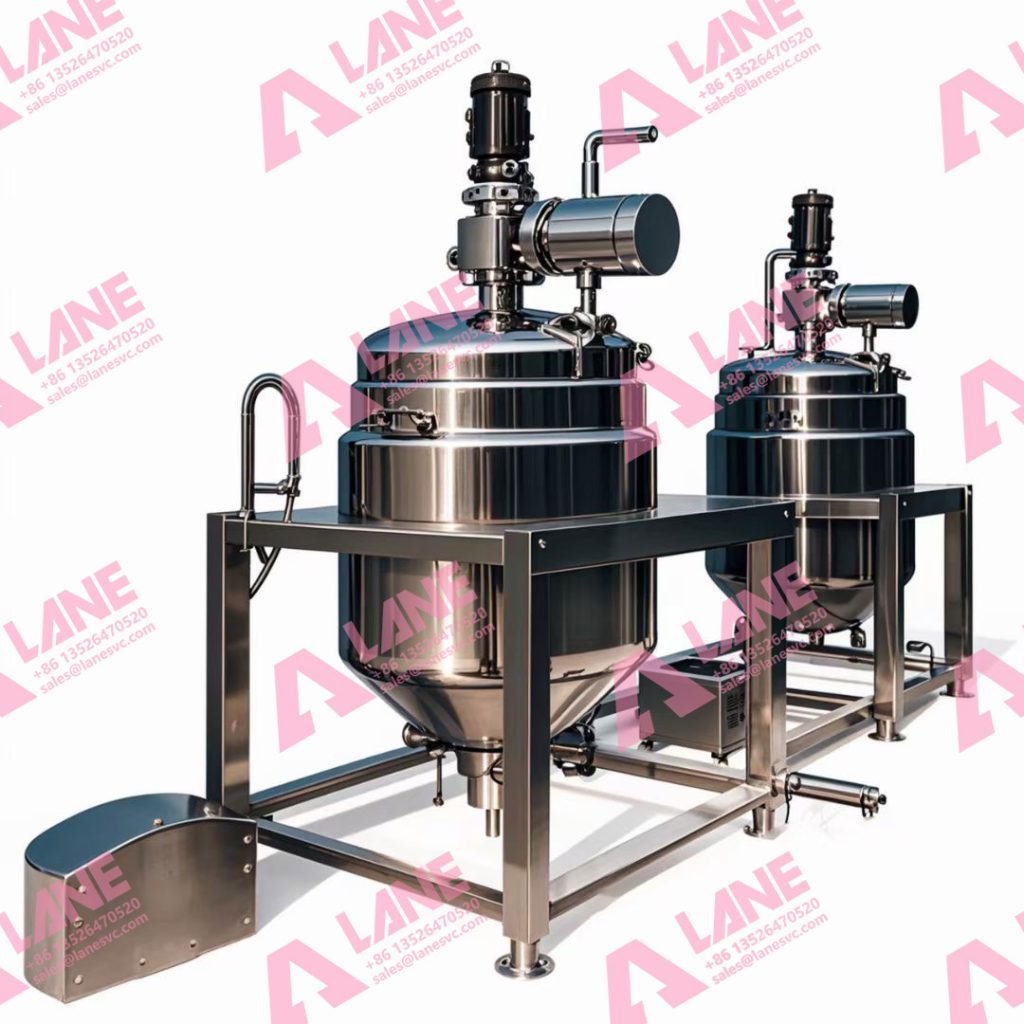

Different fertilizer processes require specific materials, designs, and configurations to achieve optimal results. Among the most commonly used reactors in the industry, many can be tailored to meet precise production needs. Leveraging Custom Reactor Equipment for Fertilizer Plants, your company can provide reactors that are not only versatile and reliable but also optimized for each unique fertilizer process.

Ideal for highly corrosive materials such as acidic or chloride-rich slurries.

Smooth glass lining prevents contamination

Excellent chemical resistance

Popular in phosphate, SSP, and organic fertilizer reactions

Best suited for reactions requiring durability and high hygiene standards.

Strong resistance to heat

Easy to clean

Ideal for organic fertilizer liquid fermentation and neutral reactions

A cost-effective solution for processes where corrosion is minimal, the Carbon Steel Reactor offers high mechanical strength and is suitable for stable reactions. Often used for large-scale fertilizer intermediates, it can also be integrated seamlessly with Custom Reactor Equipment for Fertilizer Plants to ensure consistent performance and alignment with the overall production line.

Used for dissolving, blending, and pre-reaction steps.

Ensures uniform mixing

Helps stabilize raw material performance before granulation

Choosing the right reactor type is not just a technical decision—it determines operational safety, efficiency, and product reliability.

A well-engineered reactor should offer:

Many fertilizer reactions are exothermic. Accurate heat exchange prevents runaway reactions or product defects.

Uniform mixing ensures stable particle size and reaction completeness.

Reactors must withstand acids, alkalis, and chloride ions.

Batch, semi-continuous, or fully continuous—depending on plant scale.

Crucial for preventing contamination between batches.

Pressure relief systems, sealed operation, and automated monitoring.

By incorporating Custom Reactor Equipment for Fertilizer Plants, manufacturers can ensure that every feature—from temperature control to agitation and material selection—is perfectly aligned with their specific production formula, maximizing both efficiency and product quality.

From my experience working with manufacturers across different fertilizer plants, the advantages are noticeable as soon as the line starts running:

Even small adjustments in reactor engineering can save thousands of dollars annually—something many factories only realize after switching to Custom Reactor Equipment for Fertilizer Plants, which is tailored specifically to their formulas and operational needs.

Integrating reactors into a complete fertilizer production line is essential for achieving smooth and stable operation. A reactor can’t function effectively on its own—it needs to work seamlessly with mixers, granulators, dryers, scrubbers, conveying systems, and packing machines. When everything is properly aligned, the material flows consistently through each stage without bottlenecks or unnecessary downtime. This is where Custom Reactor Equipment for Fertilizer Plants truly makes a difference, as it allows reactors to synchronize precisely with downstream processes such as granulation, pre-neutralization, or slurry preparation. By choosing Custom Reactor Equipment for Fertilizer Plants tailored to your specific formula and production capacity, manufacturers can significantly improve efficiency and maintain a steady, predictable production rhythm.

1. What size reactor should I choose for my fertilizer plant?

It depends on your hourly or daily output, reaction time, and formula. Most small-to-medium plants use 1,000–5,000 L reactors, while industrial plants may require 10,000 L+ units.

2. Which material is best—glass lined, stainless steel, or carbon steel?

Glass lined → Corrosive and acidic reactions

Stainless steel → Neutral or organic reactions

Carbon steel → Cost-effective for stable processes

Your raw material composition determines the best choice.

3. Can reactors be automated?

Yes. Modern reactors support PLC control, temperature automation, flow monitoring, and safety interlocks.

4. How long does a reactor last?

A well-maintained custom reactor typically lasts 10–20 years, depending on corrosion environment and usage intensity.

5. How do I know if my plant needs custom equipment instead of standard models?

If you face issues like corrosion, inconsistent batches, slow reactions, or downtime—custom reactors will likely solve them.

Custom reactor equipment is the backbone of modern fertilizer production, ensuring that every reaction is safe, stable, and efficient while staying aligned with your specific formula requirements. Whether you’re using a Glass Lined Reactor, Stainless Steel Reactor, Carbon Steel Reactor, or Liquid Reactor, a well-designed system provides long-term reliability and consistently higher product quality. By integrating Custom Reactor Equipment for Fertilizer Plants, manufacturers can achieve better process control and maintain the performance needed for competitive fertilizer production.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520