Release time:2025-10-22 popularity:407

In modern industrial processes, reactors play a crucial role across chemical, pharmaceutical, and fertilizer production, serving as the core equipment for efficient chemical transformation and precise product quality control. As energy costs continue to rise and sustainability becomes a central concern for industries worldwide, Energy-efficient Reactor Design has become essential for enterprises striving to optimize operational efficiency, enhance production reliability, and minimize energy expenses through advanced system integration.

By adopting Energy-efficient Reactor Design, companies can integrate advanced technologies, precise thermal management, and intelligent control systems to achieve better process stability and lower energy consumption. This innovative Energy-efficient Reactor Design approach not only enhances overall performance and competitiveness but also delivers measurable economic and environmental benefits—helping manufacturers maintain high production standards while moving toward sustainable industrial development.

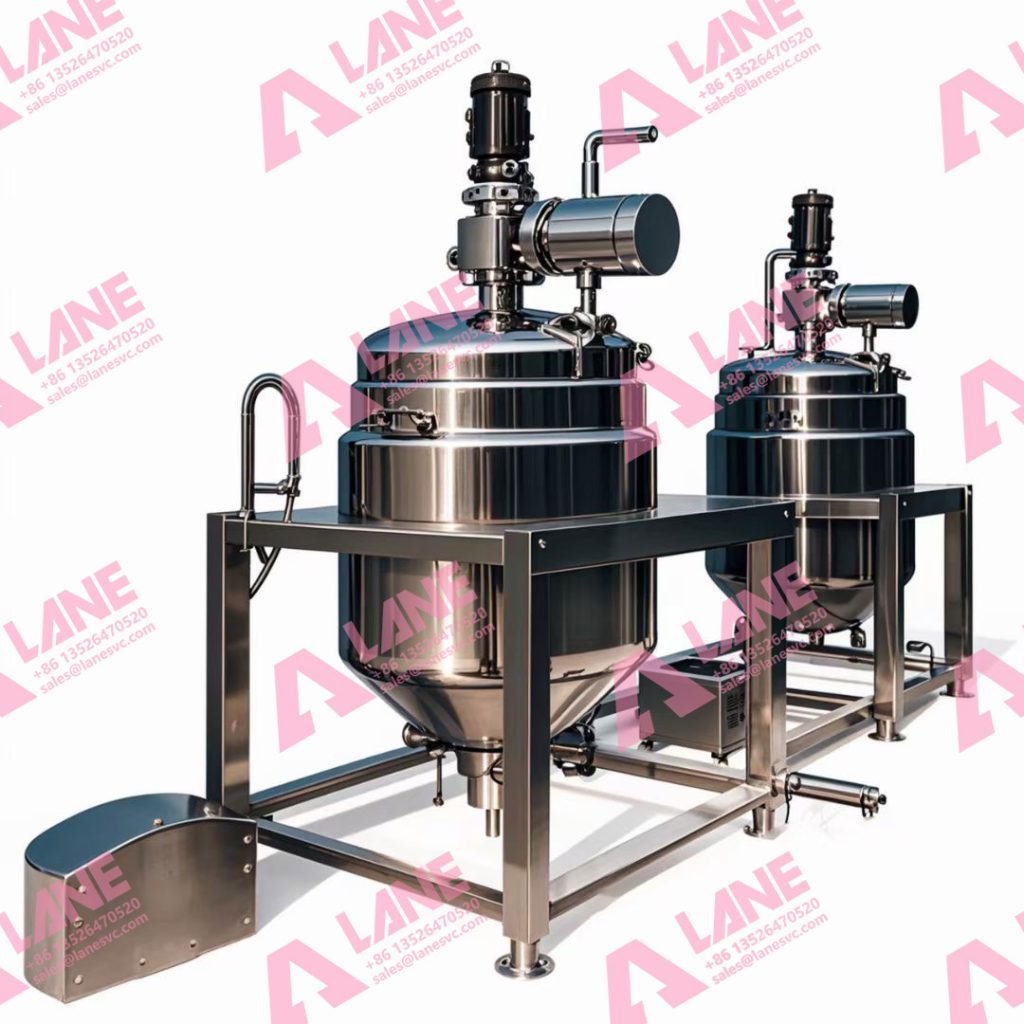

An energy-efficient reactor is engineered to maximize process performance while minimizing energy consumption, ensuring optimal results in modern industrial production. Unlike traditional designs, these reactors integrate advanced thermal management systems, optimized mixing mechanisms, and intelligent automation controls to achieve superior operational balance. Energy-efficient Reactor Design ensures that every unit of energy input directly contributes to effective chemical conversion, consistent product quality, and stable process control. By reducing unnecessary heat loss and enhancing reaction precision, this design not only minimizes waste but also improves overall operational efficiency, helping industries achieve sustainable production with lower costs and higher reliability.

Thermal Management Optimization: Efficient heat transfer and insulation reduce energy losses. Innovative designs incorporate heat exchangers, thermal jackets, and heat recovery systems to reuse energy within the process, lowering overall consumption.

Mixing and Fluid Dynamics Optimization: Low-energy impellers and optimized flow patterns enhance mixing efficiency, ensuring uniform temperature and reaction rates. Computational fluid dynamics (CFD) simulations allow engineers to refine reactor geometry for maximum energy utilization.

Intelligent Control Systems: Modern reactors use PLCs and automated monitoring systems to adjust temperature, pressure, and mixing in real-time. These systems minimize unnecessary energy usage while maintaining stable process conditions.

Material Selection: Choosing materials with high thermal conductivity and corrosion resistance extends reactor lifespan and improves energy efficiency. Stainless steel, carbon steel, and advanced alloys are often selected based on process requirements.

Energy-efficient reactor designs are increasingly adopted across industries. In chemical manufacturing, they reduce energy consumption by 15-25% while maintaining production output. In pharmaceuticals, precise temperature control enhances product consistency and minimizes batch failures. For fertilizer production, optimized reaction kinetics lead to higher yields and lower operational costs. Companies implementing Energy-efficient Reactor Design report significant return on investment (ROI) through energy savings, increased throughput, and reduced maintenance requirements, making these solutions both economically and operationally advantageous.

Investing in energy-efficient reactors brings both economic and strategic advantages for modern manufacturers. These systems help reduce operational costs through lower energy consumption and optimized resource utilization, while improving production efficiency by achieving higher throughput with the same or even reduced energy input. At the same time, they demonstrate a company’s commitment to sustainable manufacturing and corporate social responsibility, allowing enterprises to achieve immediate cost savings and reinforce their competitive edge in the global market.

At LANE Heavy Industry, we are dedicated to providing advanced reactor systems that combine innovative engineering with practical industrial performance. Our energy-efficient reactor solutions are designed to help manufacturers reduce energy consumption, improve process stability, and achieve sustainable growth. With years of expertise in reactor design, fabrication, and automation integration, we deliver customized equipment that meets diverse industry needs—from chemical production to fertilizer processing.

By partnering with LANE, clients gain access to end-to-end technical support, including system design, installation guidance, and operational optimization, ensuring long-term reliability and efficiency in every project.

As the industrial sector continues to evolve, the demand for energy-efficient solutions grows. Energy-efficient Reactor Design is no longer optional—it is a critical investment for companies aiming to improve performance, reduce costs, and support sustainable operations. At LANE Heavy Industry, we specialize in delivering high-quality, energy-efficient reactors that combine advanced engineering, reliability, and commercial value. Partner with us to enhance your production processes while optimizing energy use.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520