Release time:2025-11-17 popularity:407

It is impossible to overestimate the importance of high-quality equipment in the manufacturing of fertilizer nowadays. Fertilizer reaction vessel equipment, out of all the equipment used in fertilizer plants, is essential to the production of effective and superior fertilizers. This machinery is essential to the production process since it is in charge of the chemical reactions that convert raw materials into useful fertilizers. Selecting the appropriate reaction vessel can lower operating costs, guarantee consistent product quality, and increase production efficiency. We give manufacturers a thorough understanding of the characteristics, benefits, selection criteria, and upkeep of fertilizer reaction vessel equipment in this guide.

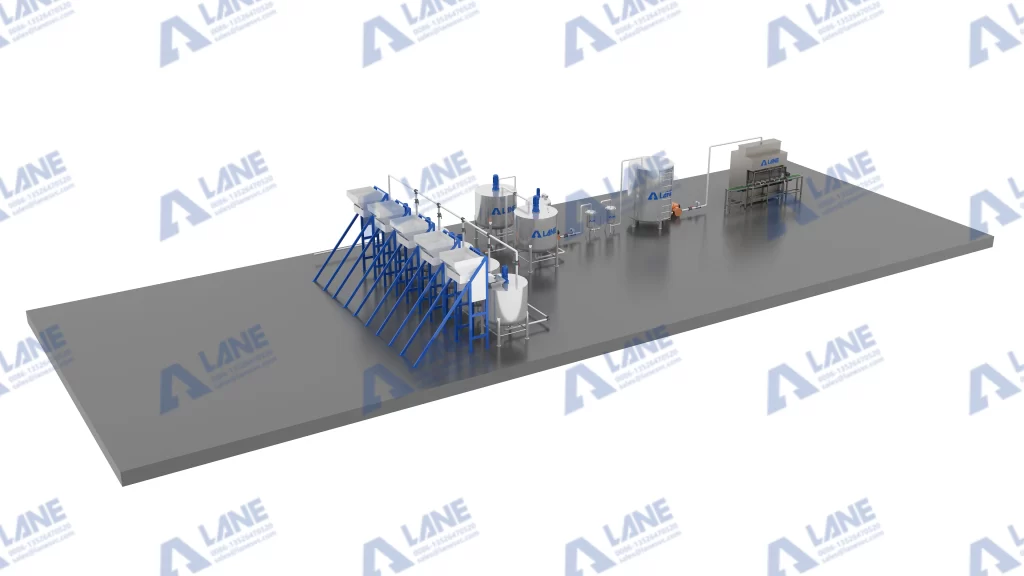

Fertilizer reaction vessel equipment is specialized machinery designed to facilitate chemical reactions in fertilizer production. Its primary function is to combine raw materials, such as phosphate, sulfuric acid, or organic matter, under controlled conditions to produce high-quality fertilizer.

These vessels are essential for producing fertilizers with consistent nutrient content, which directly affects crop performance. Modern fertilizer reaction vessel equipment also incorporates automated controls to ensure safe and efficient operations, making it suitable for both small-scale and large-scale fertilizer plants.

A variety of features included in top-notch fertilizer reaction vessel equipment guarantee product quality, safety, and production efficiency.

Key Features include of:

Together, these characteristics improve the production process and guarantee consistent outcomes while upholding operational safety for firms utilizing fertilizer reaction vessel equipment.

Selecting the appropriate fertilizer reaction vessel equipment requires careful evaluation of several factors:

Assess your daily or hourly production requirements.

Choose a vessel that aligns with current needs but allows scalability for future growth.

For acidic or corrosive reactions, select glass-lined or stainless steel vessels.

Carbon steel vessels are suitable for less aggressive chemical reactions.

Advanced automation improves precision, reduces labor, and enhances safety.

Semi-automatic systems may be adequate for smaller operations.

Check manufacturer reputation, ISO certification, and local compliance standards.

Consider after-sales support, training, and spare parts availability.

Manufacturers may make sure that the equipment they purchase for fertilizer reaction vessels satisfies operational safety regulations and production expectations by carefully assessing these factors.

Purchasing top-notch fertilizer reaction vessel equipment has several advantages:

Productivity and Efficiency

Overall manufacturing efficiency is increased by quicker reaction times and consistent mixing.

Reliable Product Quality

Uniform nutrient dispersion in fertilizer products is ensured by sophisticated monitoring.

Savings

Long-term savings are a result of less maintenance requirements, less energy use, and less downtime.

Versatility

able to handle a variety of fertilizer types, such as compound, inorganic, and organic formulas.

Security and Durability

Automated controls and corrosion-resistant materials prolong equipment life and lessen operating risks.

These benefits show why modern fertilizer businesses striving for competitive production must invest in top-notch fertilizer reaction vessel equipment.

Efficiency, durability, and safety are guaranteed when fertilizer reaction vessel equipment is properly maintained.

Important Maintenance Advice:

By adhering to these procedures, firms may ensure seamless production by preventing unplanned downtime and maintaining operational safety.

Q1: What materials are commonly used for fertilizer reaction vessel equipment?

Stainless steel, carbon steel, and glass-lined materials are widely used depending on chemical resistance requirements.

Q2: Can the equipment handle different fertilizer types?

Yes, modern fertilizer reaction vessel equipment supports organic, inorganic, and compound fertilizers.

Q3: How do I select the right capacity?

Capacity depends on production scale and market demand. Consultation with suppliers is recommended.

Q4: What maintenance is required?

Regular inspection, cleaning, lubrication, and corrosion prevention are essential for long-term use.

Q5: Is automation necessary for all fertilizer reaction vessels?

Automation is recommended for larger plants to improve efficiency, though smaller operations may use semi-automatic systems.

Q6: How does high-quality equipment improve ROI?

It ensures consistent quality, reduces downtime, saves energy, and increases production efficiency.

Q7: Are there certifications to consider when purchasing?

ISO certification, CE marking, or local agricultural standards ensure compliance and reliability.

Modern fertilizer production requires high-quality fertilizer reaction vessel equipment because it provides efficiency, safety, and reliable product quality. Manufacturers can guarantee seamless operations and long-term profitability by comprehending its features, assessing production capacity, taking automation into account, and correctly maintaining equipment. Selecting the appropriate reaction vessel is an investment in operational dependability, product uniformity, and market competitiveness in addition to immediate production needs. The fertilizer reaction vessel equipment is the foundation of any successful manufacturing facility for fertilizer manufacturers.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520