Release time:2025-12-15 popularity:407

Choosing the right chemical reactor size is among the most important decisions in any chemical production operation. How to choose the right chemical reactor size? is a question that engineers, plant managers, and process designers frequently encounter, as the reactor’s size has a direct impact on production efficiency, operational safety, product quality, and overall costs.

In this comprehensive guide, we will examine the key factors that influence reactor sizing, provide practical tips for selecting the optimal reactor, and discuss how modern industrial practices and advanced equipment can help you achieve higher efficiency and more reliable production outcomes. By understanding how to choose the right chemical reactor size? professionals can make informed decisions that enhance both performance and long-term operational success.

The size of a chemical reactor affects multiple aspects of your production line:

Production capacity: An undersized reactor may limit throughput, while an oversized reactor increases costs and energy consumption.

Reaction efficiency: Reactor volume influences mixing, heat transfer, and reaction kinetics.

Safety: Proper sizing prevents overpressure, excessive temperature rises, and other hazards.

Understanding how to choose the right chemical reactor size? is essential for balancing productivity, efficiency, and safety. By considering reaction type, production scale, and thermal management, engineers can confidently determine the optimal reactor. Ultimately, knowing how to choose the right chemical reactor size? ensures maximum operational efficiency while maintaining product quality and long-term reliability.

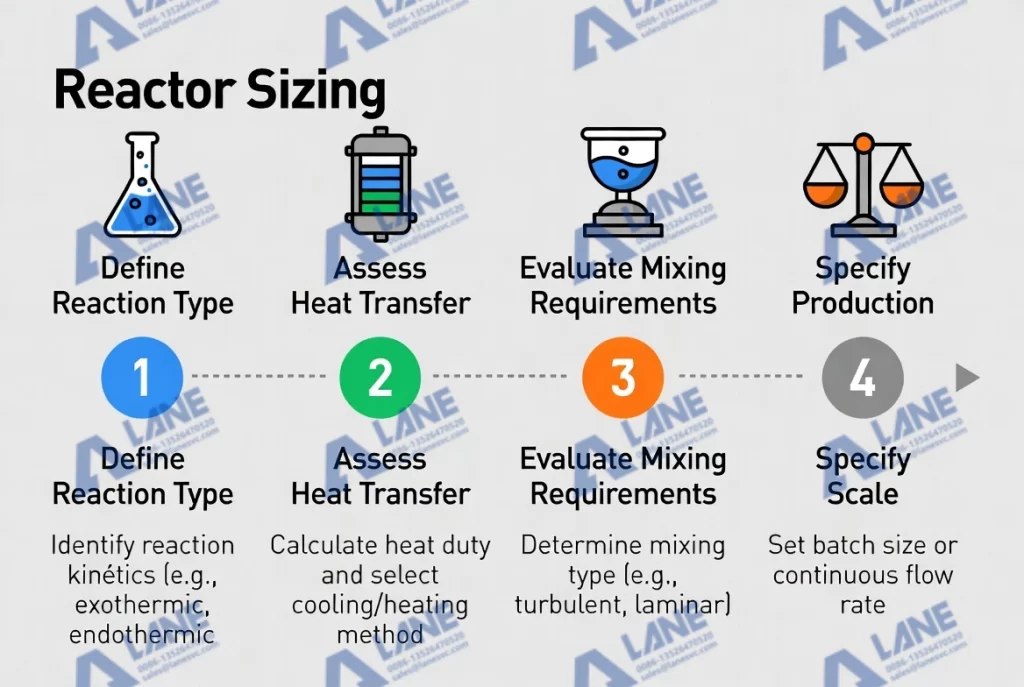

1. Reaction Type and Kinetics

Different chemical reactions require different residence times and mixing characteristics. For fast reactions, smaller reactors with high mixing efficiency may suffice. Slower reactions may need larger volumes to ensure complete conversion. Engineers must calculate the reaction kinetics before selecting the reactor size.

2. Production Scale

The intended production scale—laboratory, pilot, or industrial—greatly influences reactor sizing. For large-scale industrial production, a detailed evaluation of capacity requirements ensures that the reactor can handle peak loads without underperformance.

3. Heat Transfer Requirements

Some reactions are highly exothermic or endothermic. The reactor must be sized to allow efficient heat removal or supply. Improper sizing can lead to hot spots, inefficient reactions, or safety risks.

4. Mixing and Mass Transfer

Adequate mixing is critical to ensure uniformity and maximize reaction efficiency. The size of the reactor affects the design of impellers, baffles, and mixing speed. Engineers must evaluate how reactor volume interacts with mixing requirements.

5. Material and Equipment Limitations

Material compatibility, available equipment, and plant layout constraints may also influence reactor selection. In many cases, optimizing for space and equipment availability is as important as the chemical requirements.

At LANE (Henan LANE Heavy Industry Machinery Technology Co., Ltd.), we specialize in designing chemical reactors that cater to both industrial and commercial production requirements. With extensive experience in large-scale chemical processing and equipment manufacturing, LANE applies practical engineering expertise to every reactor design.

Our engineers carefully assess reaction kinetics, production demands, and thermal management strategies to guide customers in how to choose the right chemical reactor size? By combining precise calculations with advanced design software, LANE ensures that each reactor maximizes production efficiency, enhances safety, and delivers reliable long-term operational performance.

By following these tips, you can answer the question how to choose the right chemical reactor size? effectively and make decisions backed by engineering principles.

Q1: How do I know if my reactor is too small or too large?

A: Compare the actual production output and reaction efficiency with your design goals. An undersized reactor may limit throughput, while an oversized reactor can waste energy and resources.

Q2: Can the reactor size be adjusted after installation?

A: Limited adjustments can be made with process modifications, but major changes usually require replacement or retrofitting.

Q3: Does reactor material affect sizing?

A: Yes. Material properties influence heat transfer, corrosion resistance, and mechanical strength, which can affect optimal reactor volume.

Q4: How does production scale influence reactor size?

A: Larger production volumes require reactors that can safely handle increased material quantities while maintaining reaction efficiency and safety.

Knowing how to choose the right chemical reactor size? is essential for any chemical production operation. By carefully evaluating reaction type, production scale, heat and mass transfer, and material constraints—and leveraging the expertise of experienced manufacturers like LANE—you can select a reactor that not only maximizes efficiency and ensures safety but also supports long-term growth.

Understanding how to choose the right chemical reactor size? is more than a technical decision; it is a strategic investment in production reliability, operational consistency, and high-quality end products.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520