Release time:2025-11-20 popularity:407

Glass lined reactors (GLRs) are widely used in chemical, pharmaceutical, and fertilizer industries due to their exceptional resistance to corrosion and contamination. However, even the most durable glass lining can accumulate residues over time, reducing heat transfer efficiency and potentially compromising product quality. Knowing how to clean a glass lined reactor? properly is critical to maintaining performance, extending equipment lifespan, and ensuring safe operation.

In this guide, we’ll walk through the step-by-step cleaning process, practical tips from experienced operators, and safety precautions that make the task effective and reliable.

The glass lining in reactors is chemically inert and smooth, preventing reactions with most chemicals. This feature protects both the product and the equipment but also requires delicate handling. Aggressive cleaning methods, abrasive tools, or rapid temperature changes can cause cracks or scratches in the lining. Therefore, understanding the unique properties of GLRs is the first step in proper maintenance.

Operators should look for indicators that the reactor needs maintenance before beginning the cleaning procedure:

Early detection of these indicators avoids potential harm and expensive downtime.

When cleaning a reactor with a glass lining, safety is crucial, especially when understanding how to clean a glass lined reactor. Essential safety measures include using proper PPE such as gloves, eyewear, chemical-resistant clothing, and respiratory protection. The reactor should be fully purged and vented to remove any residual chemicals. To prevent thermal shock, operators must avoid sudden temperature changes, gradually adjusting the reactor temperature if it was recently in use. Before cleaning begins, trained experts should inspect the lining for weak spots or microcracks to ensure safe and effective operation.ng.

Completely drain the contents and disconnect utilities, including steam, heating, or cooling circuits. Lockout/tagout procedures are essential to ensure no accidental activation occurs during cleaning.

Rinse the reactor with warm water to soften residues. Temperature control is crucial: water that is too hot may cause thermal stress, and cold water may not remove sticky deposits effectively. Operators often circulate water using the reactor’s own agitator to improve rinsing.

Choose a cleaning agent based on the residue type:

Organic residues: Use mild alkaline detergents.

Inorganic scaling: Acidic cleaners are effective, but strong acids should be avoided or used under expert supervision.

Never use abrasive powders or metal tools that can scratch the glass lining.

Apply the cleaner, allow sufficient contact time, and use gentle agitation to enhance cleaning.

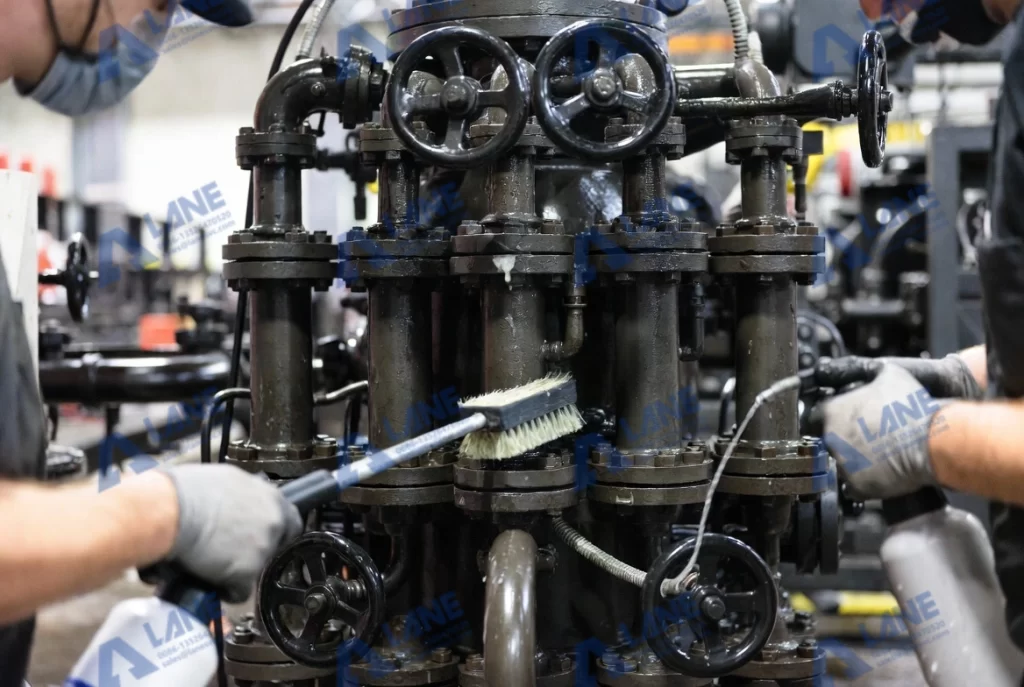

For stubborn residues, use soft brushes or specially designed non-metallic tools. Avoid metal scrapers, as they can permanently damage the glass surface. Experienced technicians often combine gentle scrubbing with chemical cleaning to remove tough buildup safely.

Thoroughly rinse the reactor until no detergent or chemical traces remain. Test the pH to ensure the reactor interior is neutral. This step is crucial to prevent contamination during the next production cycle.

Allow the reactor to air-dry or use low-temperature drying methods. Avoid high-heat drying, which may induce thermal stress. Proper drying prevents corrosion in non-glass parts and ensures the reactor is ready for the next batch.

A proper inspection is essential when learning how to clean a glass lined reactor. After cleaning, operators should check for cracks, residues, and damage to the agitator or fittings, using visual checks and spark or ultrasonic testing. These steps help maintain safety and extend equipment life.

Common cleaning issues also need attention when considering how to clean a glass lined reactor. Heavy scaling may require mild acid treatments, while discoloration can be corrected with neutralizing rinses. Residual solvents should be removed through proper ventilation and rinsing. If scratches appear, avoid abrasive methods and seek expert repair, ensuring the correct approach to how to clean a glass lined reactor.

The ideal cleaning frequency depends on industry and material processed:

Chemical plants: 1–2 times per production cycle depending on residue buildup.

Fertilizer plants: Typically after every batch or weekly, depending on scaling risk.

Pharmaceutical production: Stringent cleaning after every batch to avoid contamination.

Factors like production volume, material type, and process conditions influence the cleaning schedule.

Maintaining a cleaning log for each batch, avoiding rapid temperature swings, using gentle cleaning agents suitable for glass lining, and regularly inspecting the reactor while ensuring operators are properly trained are essential steps in keeping equipment safe and efficient. Following these practices not only reduces the risk of lining damage but also improves product quality and enhances overall operational safety, making them an important part of understanding how to clean a glass lined reactor.

1. Can I use metal brushes to clean a GLR?

No. Metal brushes can scratch the lining and reduce its lifespan. Use soft, non-metallic tools.

2. How often should a GLR be cleaned in a fertilizer plant?

Typically weekly or after each batch, depending on residue type.

3. Is high-temperature drying safe for GLRs?

No. High temperatures can cause thermal stress and damage the lining.

4. What chemical cleaners are safe for glass lined reactors?

Mild alkaline detergents for organic residues; weak acids for inorganic scaling. Strong acids must be used with caution.

5. How do I check for micro-cracks after cleaning?

Visual inspection, spark tests, or ultrasonic methods are commonly used by experienced technicians.

Knowing how to clean a glass lined reactor? is vital for any industrial operator. Following safe, step-by-step procedures ensures effective residue removal, protects the glass lining, and extends the equipment’s life. Regular cleaning, careful inspection, and proper maintenance practices allow plants to operate efficiently and maintain high product quality.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520