Release time:2025-10-30 popularity:407

In modern chemical, pharmaceutical, and fertilizer industries, the industrial reactor system serves as the core of every production process. It enables the controlled transformation of raw materials into valuable end products with efficiency, precision, and safety. The performance of your reactor directly influences product quality, production cost, and overall plant efficiency. Choosing the right reactor system is not just a technical decision — it’s a strategic investment in long-term reliability and sustainability. A well-matched reactor enhances operational stability, reduces energy consumption, minimizes downtime, and ensures consistent product quality. For manufacturers aiming to achieve higher productivity and safer, cleaner production, selecting the proper industrial reactor system is the foundation of success.

Before selecting a reactor, consider your production needs carefully:

Production Scale: Small, medium, or large-scale operations.

Process Type: Batch reactions, continuous processes, or specialty chemical reactions.

Raw Material Characteristics: Corrosive, viscous, or temperature-sensitive materials.

Product Requirements: Granule size, purity, and stability.

Budget and Energy Considerations: Balance cost with efficiency and long-term ROI.

Assessing these factors will help you choose a reactor that aligns with your plant’s operational goals.

Designed for handling highly corrosive materials like acids and bases, the glass lined reactor offers excellent chemical resistance and durability. It is easy to clean and suitable for high-temperature reactions. Advantages: Corrosion-resistant, long-lasting, and ideal for chemical, pharmaceutical, and fertilizer production.

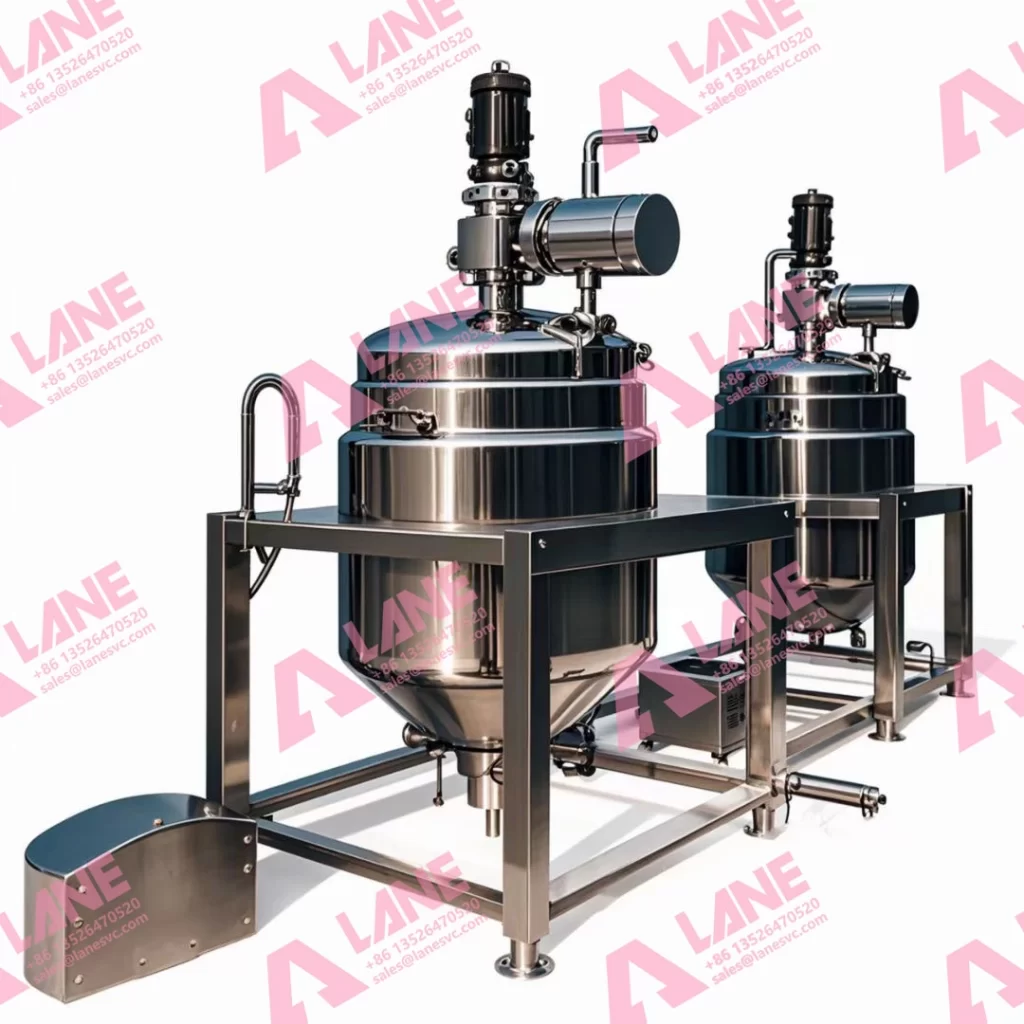

The stainless-steel reactor is widely used in pharmaceuticals, food processing, and chemical manufacturing. It resists corrosion, withstands pressure, and ensures product purity. Advantages: Durable, high-strength, corrosion-resistant, and suitable for most industrial processes.

For non-corrosive chemical reactions, a carbon steel reactor provides an affordable and robust solution. It is suitable for large-scale processes where chemical resistance is less critical. Advantages: Cost-effective, strong, and reliable for standard chemical reactions.

The liquid reactor is designed for handling liquid-phase reactions, mixing, and continuous processing. It offers high efficiency and is perfect for continuous chemical reactions. Advantages: Energy-saving, high efficiency, and easy to integrate into automated production lines.

When choosing an industrial reactor system, it’s crucial to evaluate key technical and operational factors to ensure long-term reliability and safety. Start with the material of construction—it should provide excellent resistance to corrosion, pressure, and temperature fluctuations based on your raw materials. Next, consider the volume and capacity to match your production scale and output goals. Advanced automation and control systems are equally important, allowing real-time monitoring and precise regulation of temperature, pressure, and mixing speed.

In addition, pay close attention to safety features such as anti-leak seals, overpressure protection, and explosion-proof designs. A well-designed reactor with these elements not only ensures stable and efficient operation but also minimizes risks and downtime, helping your plant maintain consistent performance and product quality.

Partnering with an experienced industrial reactor system supplier ensures smooth installation, operation, and maintenance.

For instance, LANE Heavy Industry provides complete reactor solutions and supports plants worldwide with professional guidance and service.

Proper installation and regular maintenance are vital to extending the service life of an industrial reactor system. A well-planned site layout ensures sufficient space for equipment operation, safety checks, and maintenance activities. Before starting production, the commissioning process should include comprehensive testing and precise calibration to verify performance and safety standards.

Regular maintenance helps prevent unexpected downtime and ensures stable, long-term operation. Routine tasks such as lubrication, inspection, and timely replacement of worn components are essential to maintain efficiency and reliability. By following these maintenance practices, plants can improve reactor performance, reduce repair costs, and achieve consistent production results.

Choosing the right industrial reactor system is crucial for efficiency, safety, and long-term profitability. By understanding your production requirements, evaluating reactor types, and selecting a reliable supplier, your plant can achieve consistent high-quality output.

At Henan LANE Heavy Industry Machinery Technology Co., Ltd., we provide complete reactor solutions — from glass-lined and stainless-steel reactors to carbon steel and liquid reactors — helping partners worldwide build efficient, safe, and automated industrial processes.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520