Release time:2026-01-29 popularity:407

With the rapid growth of sustainable agriculture and organic fertilizer projects worldwide, reactors have become a core piece of equipment for composting and fertilizer production. However, many project failures do not stem from reactor design or mechanical performance, but from a more fundamental issue: the improper selection and preparation of organic waste raw materials for reactor systems.

Understanding what materials are suitable, how they behave during processing, and how they influence composting efficiency is essential for stable operation and consistent fertilizer quality. This practical guide explains how to evaluate organic waste raw materials for reactor use, with a focus on composting and organic fertilizer production.

In composting and fertilizer production, organic waste raw materials for reactor systems refer to biodegradable inputs that can be biologically decomposed under controlled conditions. These materials provide carbon, nitrogen, moisture, and microbial nutrients necessary for efficient fermentation.

Common categories include:

Each material behaves differently inside a reactor, affecting temperature rise, oxygen demand, and fermentation time. Selecting the right organic waste raw materials for reactor applications is the first step toward stable and predictable composting results.

Not all organic materials are equally suitable for reactor-based composting. The following parameters should be evaluated before feeding materials into the system.

Carbon-to-Nitrogen Ratio (C/N)

An ideal C/N ratio typically ranges between 25:1 and 30:1. Animal manure alone is often nitrogen-rich, while crop residues are carbon-heavy. Proper blending of organic waste raw materials for reactor use ensures balanced microbial activity and avoids ammonia loss.

Moisture Content

Most reactor systems perform best when moisture content is controlled between 50% and 65%. Excess water reduces aeration, while overly dry materials slow microbial activity. Pre-adjustment is often required for food waste and fresh manure.

Particle Size and Structure

Large particle sizes reduce contact area, slowing decomposition. However, overly fine materials may compact and block airflow. Shredding and mixing are essential preprocessing steps when handling organic waste raw materials for reactor applications.

Animal Manure

Animal manure is one of the most widely used organic waste raw materials for reactor systems due to its high nutrient content and active microbial population. Poultry manure accelerates heating but requires carbon-rich materials to prevent nitrogen loss.

Crop Residues

Straw, stalks, and husks improve aeration and structure. When used correctly, they stabilize fermentation and improve final compost texture. These materials are particularly valuable when processing wet organic waste raw materials for reactor-based composting.

Food and Kitchen Waste

Food waste decomposes rapidly but requires strict moisture control. Mixing it with fibrous materials helps stabilize reactor operation and prevents odor issues.

Proper preprocessing significantly improves reactor efficiency and product consistency.

Without these steps, even high-quality organic waste raw materials for reactor systems can cause unstable fermentation or incomplete composting.

When correctly prepared, organic waste raw materials for reactor use produce compost with:

The quality of raw materials directly determines downstream fertilizer efficiency and market value.

Many operators underestimate the importance of material compatibility. Common mistakes include:

Avoiding these issues ensures long-term stability when working with organic waste raw materials for reactor applications.

Q1: Can all organic waste be used in a composting reactor?

Not all organic waste is suitable. Materials must be biodegradable, free from toxic contaminants, and properly balanced in moisture and nutrients. Selecting appropriate organic waste raw materials for reactor use is essential for safe operation.

Q2: Do different reactors require different raw materials?

Yes. Aerobic reactors, rotary drums, and vertical fermenters have different airflow and mixing mechanisms. Raw materials should be adjusted accordingly.

Q3: Is preprocessing always necessary?

In most cases, yes. Crushing, mixing, and moisture adjustment significantly improve reactor performance and compost quality.

Q4: How does raw material quality affect fertilizer output?

High-quality organic waste raw materials for reactor systems result in more stable compost, better granulation, and higher market acceptance of the final fertilizer.

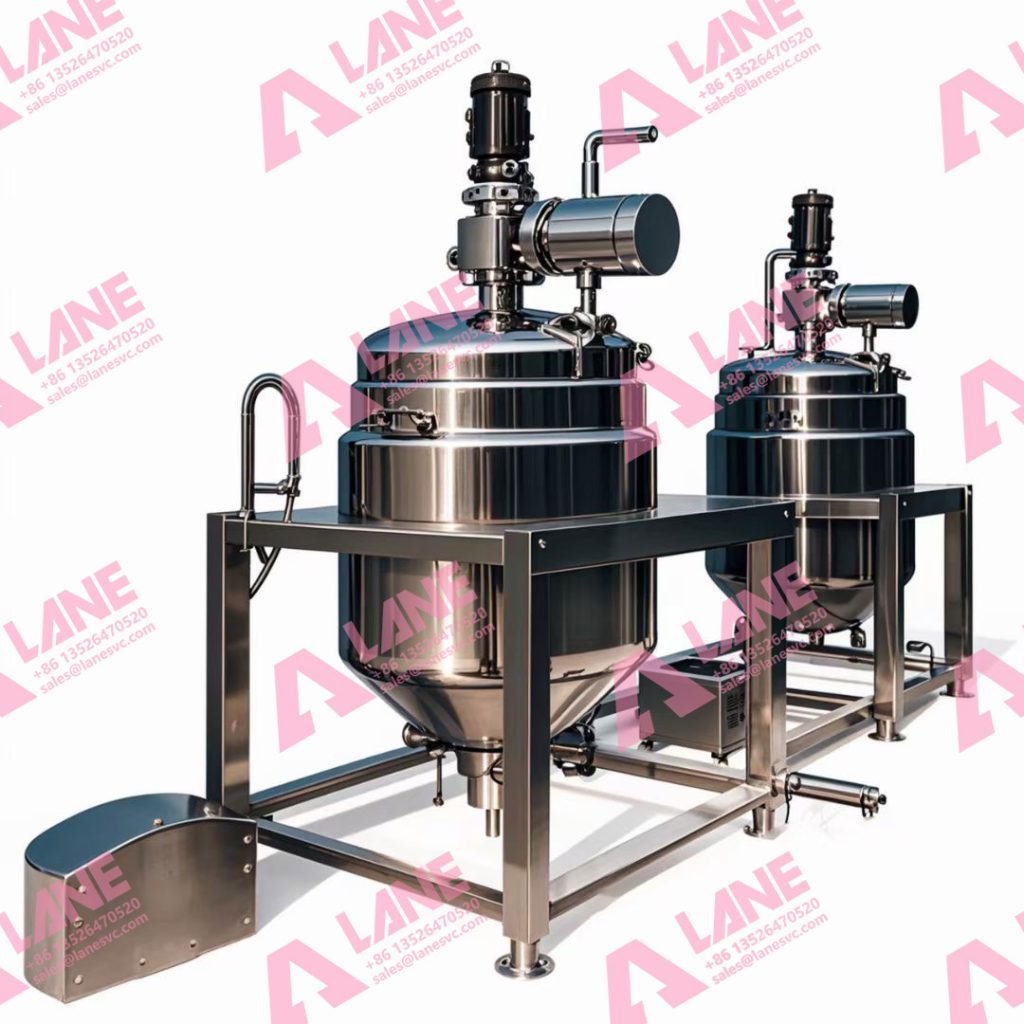

As a specialized manufacturer of organic fertilizer and composting equipment, LANE Heavy Industry has extensive experience in handling diverse organic waste raw materials for reactor applications. Our reactor systems are designed to accommodate variable material compositions while maintaining stable fermentation conditions.

LANE provides not only equipment, but also material evaluation guidance, helping customers optimize raw material combinations for composting and fertilizer production. From small-scale farms to industrial fertilizer plants, LANE solutions are engineered to improve efficiency, reduce operational risk, and maximize resource recovery.

Successful composting and fertilizer production depend on more than advanced machinery. The careful selection, preparation, and management of organic waste raw materials for reactor systems determine fermentation efficiency, product quality, and long-term operational stability.

By understanding material properties and applying practical preprocessing strategies, operators can turn organic waste into a valuable resource and achieve sustainable, profitable fertilizer production.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520