Release time:2026-01-27 popularity:407

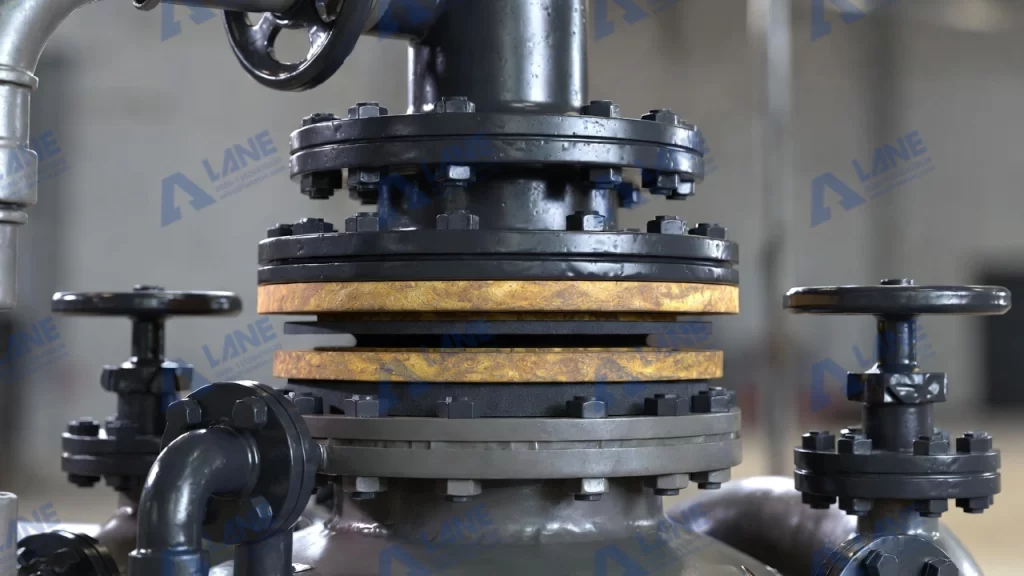

Industrial reactors are critical assets in chemical, pharmaceutical, and fertilizer production plants. Their operational efficiency directly impacts productivity, safety, and profitability. One of the most persistent challenges for reactor operators is corrosion, which can compromise reactor integrity, reduce lifespan, and increase maintenance costs.

Implementing Reactor Corrosion Resistance Technology has emerged as a proven strategy to address these challenges. This technology focuses on using advanced materials, protective coatings, and innovative design practices to prevent corrosion, ensuring reactors operate safely and efficiently for decades.

Corrosion can affect reactors in multiple ways:

Adopting Reactor Corrosion Resistance Technology helps minimize these risks, creating safer work environments and reducing unexpected production interruptions.

Choosing the right material is the foundation of corrosion resistance. Common approaches include:

These material choices extend reactor lifespan and reduce the frequency of maintenance interventions.

Protective coatings are an essential component of Reactor Corrosion Resistance Technology:

Proper coating application prevents direct contact between corrosive chemicals and reactor surfaces, reducing degradation rates and associated maintenance costs.

Corrosion resistance is not only about materials but also about smart reactor design:

Optimized design works hand-in-hand with materials and coatings to maximize protection and operational efficiency.

LANE Heavy Industry specializes in advanced Reactor Corrosion Resistance Technology solutions for industrial reactors. Unlike providers who sell single components, LANE focuses on integrated, process-oriented systems that are customized to production needs.

LANE’s approach includes:

By leveraging LANE’s expertise, companies not only enhance reactor lifespan but also achieve significant cost savings and safer operations.

Adopting corrosion-resistant technologies offers tangible benefits:

Investing in corrosion resistance is not an expense; it is a long-term strategy that pays off by reducing operational risks and increasing profitability.

Q1: What is Reactor Corrosion Resistance Technology?

It is a set of materials, coatings, and design practices aimed at preventing corrosion in industrial reactors to improve lifespan and performance.

Q2: Why is corrosion a major concern for reactors?

Corrosion can cause structural failure, contaminate processes, increase maintenance downtime, and raise operational costs.

Q3: Can existing reactors be upgraded with corrosion resistance technology?

Yes. Many older reactors can be retrofitted with protective coatings, linings, or material modifications to extend their service life.

Q4: How does this technology reduce maintenance costs?

By preventing corrosion, reactors require fewer repairs and replacements, lowering labor and material expenses over time.

Q5: Which industries benefit most from Reactor Corrosion Resistance Technology?

Chemical, pharmaceutical, fertilizer, and petrochemical industries, or any operation involving corrosive materials and high-temperature processes.

Implementing Reactor Corrosion Resistance Technology is no longer optional—it is essential for any facility aiming to maximize reactor lifespan, reduce maintenance costs, and ensure safe, reliable operations. With the right combination of materials, coatings, and design, industrial reactors become long-lasting assets that support operational efficiency, product quality, and profitability.

Working with experts like LANE Heavy Industry ensures that corrosion resistance is applied comprehensively, tailored to your process needs, and backed by professional technical support, delivering measurable benefits in both safety and cost savings.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520