Release time:2025-10-28 popularity:407

In chemical and fertilizer manufacturing, understanding Reactor Design and Working Principle is crucial for ensuring efficient, safe, and high-quality production. Reactors, or reaction vessels, are the heart of many industrial processes, handling chemical reactions, blending raw materials, and controlling temperature and pressure. Proper reactor design directly impacts production efficiency, product uniformity, and energy consumption. By mastering Reactor Design and Working Principle, manufacturers can optimize their processes, reduce operational risks, and enhance the overall performance of their plants.

Reactor design is all about carefully planning and engineering a reaction vessel to carry out chemical or physical processes in the most efficient and safe way possible. It considers factors like material strength, reaction time, energy use, and how different substances interact under pressure and temperature. The working concept behind a reactor focuses on what happens inside during operation—how heat and mass are transferred, how mixing is achieved, and how reaction rates are controlled to ensure consistent results.

There are many types of reactors used across industries, from stirred tank reactors and tubular systems to batch and continuous reactors, each serving different production goals. Choosing the right design depends on the nature of the raw materials, process conditions, and the quality requirements of the final product. By understanding how these systems operate, engineers can ensure that each reactor performs reliably, maintains safety standards, and delivers optimal results in chemical and fertilizer manufacturing.

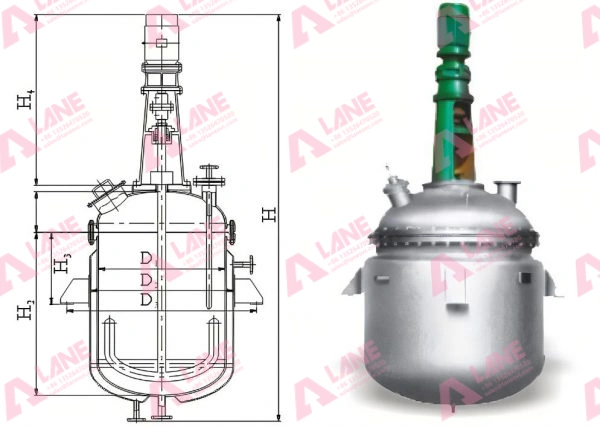

Understanding how a reactor is built and how it operates starts with knowing its main components and their functions. The reactor shell forms the core structure and must be made from materials that can handle high pressure, temperature, and potential corrosion—especially in chemical or fertilizer production. Inside the reactor, the agitator and rotor play a vital role by keeping materials well mixed and ensuring that reactions happen evenly throughout the vessel, preventing hotspots or uneven product formation.

Additional internal parts, such as baffles and flow guides, help improve mixing efficiency and stabilize the movement of fluids or slurries inside the reactor. The heating and cooling systems are equally important, as they maintain the ideal temperature range required for each process. Together, these elements ensure that the reactor performs safely, efficiently, and consistently supporting smooth operation and long-term reliability in industrial environments.

Understanding Reactor Design and Working Principle directly influences production outcomes:

Mixing Efficiency: Proper agitator design ensures uniform chemical reactions and prevents material settling.

Reaction Control: Reactor geometry and internals affect heat and mass transfer, impacting reaction speed and yield.

Energy Consumption: Efficient design reduces unnecessary energy usage, lowering operational costs.

Optimized reactor design enhances the overall productivity, safety, and reliability of chemical and fertilizer plants.

A successful reactor design relies on several key factors, including material properties (such as corrosiveness, viscosity, and particle size), operating temperature and pressure, and ease of maintenance. Each parameter must be carefully evaluated to ensure the reactor operates safely and efficiently under industrial conditions. A thorough understanding of Reactor Design and Working Principle helps engineers balance performance, safety, and cost-effectiveness. By optimizing heat transfer, mixing, and process control, manufacturers can achieve reliable, energy-efficient, and long-lasting reactor systems for chemical and fertilizer production.

Having a solid understanding of Reactor Design and Working Principle can make a big difference in how smoothly and efficiently your plant runs. A well-engineered reactor ensures higher yields and consistent product quality, since every reaction happens more evenly and predictably. It also helps reduce energy use and raw material waste, keeping your operation both cost-effective and environmentally friendly.

Beyond efficiency, smart reactor design means better safety and easier control. With precise management of temperature, pressure, and mixing, operators can avoid downtime and minimize risks. Plus, today’s advanced reactors are designed for automation and intelligent monitoring, allowing real-time adjustments and more stable production. In short, understanding how reactors are built and how they work helps manufacturers run safer, cleaner, and more productive facilities.

Mastering Reactor Design and Working Principle is key for manufacturers aiming to enhance efficiency, safety, and product quality. Every detail—from choosing the right materials and reactor type to optimizing mixing, heat exchange, and pressure control—plays a major role in how well the system performs. A well-designed reactor doesn’t just improve chemical reaction efficiency; it also lowers operational costs, reduces downtime, and ensures stable long-term production.

Working with a professional reactor manufacturer provides an added advantage. Expert suppliers can design reactors that meet your plant’s specific process requirements, ensuring reliable performance and easy maintenance. By fully applying the principles of Reactor Design and Working Principle, chemical and fertilizer producers can build smarter, more sustainable plants that deliver consistent results, higher profitability, and long-term safety in every operation.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520