Release time:2025-10-23 popularity:407

In the competitive industrial landscape, efficiency is a key driver of productivity, cost reduction, and sustainable growth. Whether in chemical manufacturing, pharmaceuticals, or fertilizer production, the performance of your reactor systems plays a critical role in determining overall operational efficiency. Reactor Equipment Configuration—the strategic design and setup of reactor systems—can significantly impact throughput, energy consumption, and product quality. By optimizing reactor configurations, companies can unlock higher efficiency, reduce operational costs, and enhance safety.

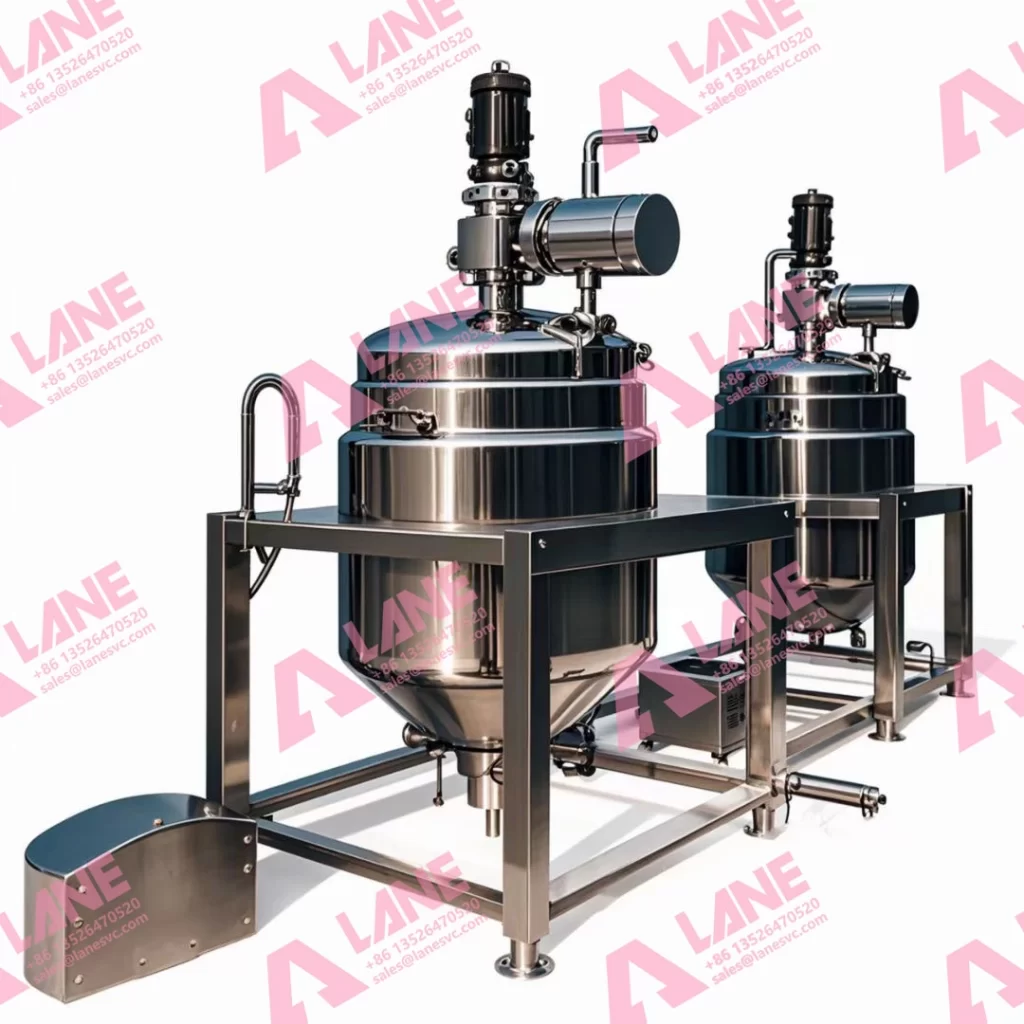

Reactor Equipment Configuration refers to the comprehensive arrangement of reactor systems, including the type of reactor, auxiliary equipment, piping, and control systems. Proper configuration ensures that chemical reactions proceed efficiently, heat transfer is optimized, and materials flow smoothly throughout the process. Conversely, poor configuration can lead to reduced productivity, increased energy consumption, and higher maintenance costs. Reactor configuration involves multiple elements:

Agitation and mixing systems to ensure uniform reactant distribution

Heating and cooling mechanisms for precise temperature control

Material feeding and discharge systems for smooth operation

Automation and control systems for process monitoring and optimization

By carefully evaluating these factors, industries can tailor reactor configurations to their specific production needs.

Several factors directly influence reactor efficiency:

Reactor Type and Design: The choice of reactor significantly impacts the reaction kinetics and heat transfer efficiency. For example, a well-designed stirred-tank reactor with optimized impellers ensures proper mixing and uniform temperature distribution, reducing reaction time and improving product consistency.

Heating and Cooling Systems: Efficient heat management is crucial for chemical reactions. Advanced reactor configurations incorporate energy-efficient heating and cooling systems to maintain optimal reaction conditions, minimize energy losses, and prevent overheating or under-reacting.

Material Handling and Flow Optimization: Efficient feeding and discharge systems reduce downtime and prevent bottlenecks. Properly designed piping and conveyors ensure that raw materials and intermediate products move smoothly through the process, enhancing overall productivity.

Automation and Process Control: Modern reactor setups integrate PLC and SCADA systems for real-time monitoring and automated control. These systems enable precise adjustments to temperature, pressure, and mixing speed, ensuring reactions remain within optimal conditions and minimizing human error.

Adopting advanced strategies can further enhance efficiency and productivity:

Optimized Mixing Systems: High-performance impellers and advanced fluid dynamics designs improve mass transfer and reaction rates, reducing reaction times and energy consumption.

Intelligent Control Systems: Automation systems with predictive algorithms and process analytics allow operators to anticipate potential issues, optimize reaction parameters, and maintain consistent product quality.

Energy-Efficient Design: Reactor configurations that maximize heat recovery, reduce energy losses, and use sustainable materials contribute to lower operational costs and improved environmental performance.

Modular and Flexible Configuration: Modular designs allow for scalable production and easier maintenance, enabling companies to adjust production capacity according to market demand without extensive downtime.

A chemical production facility recently upgraded its reactor systems by installing high-efficiency impellers to enhance mixing, integrating automated temperature and pressure control systems, and optimizing material feeding and discharge processes. These strategic improvements ensured smoother operations, better heat and mass transfer, and more precise reaction control throughout the production line.

As a result, the plant experienced a 15% increase in overall production capacity, a 10% reduction in energy consumption, and significantly improved product consistency. This case clearly demonstrates how implementing an advanced reactor configuration can deliver tangible operational benefits, including higher efficiency, reduced costs, and enhanced reliability in industrial chemical processes.

Selecting the optimal reactor configuration demands a thorough evaluation of multiple factors. Production capacity needs must be matched with the appropriate reactor size and type to ensure smooth throughput, while material characteristics—such as chemical properties, viscosity, and reaction kinetics—play a crucial role in determining the most effective setup.

Additionally, companies should assess budget constraints and potential ROI, weighing the investment in advanced Reactor Equipment Configuration against long-term efficiency gains and cost savings. Reliable technical support, including professional installation and maintenance, is essential for sustaining optimal Reactor Equipment Configuration performance. Partnering with experienced suppliers and engineers ensures a Reactor Equipment Configuration tailored to specific operational goals and production requirements.

In today’s industrial environment, maximizing efficiency is essential for competitiveness and profitability. By implementing advanced Reactor Equipment Configuration, companies can optimize reaction kinetics, reduce energy consumption, enhance safety, and improve overall productivity. A well-designed reactor setup is not just an operational necessity—it is a strategic investment that drives sustainable growth, cost savings, and high-quality output.

For industrial enterprises seeking to enhance their reactor performance, consulting with experts and adopting tailored, advanced configurations can be the key to achieving long-term success.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520