Release time:2025-10-25 popularity:407

In modern fertilizer production, achieving high efficiency, consistent product quality, and sustainable operations depends heavily on the technology and equipment used. Among these, reactors play a central role. The Reactor Manufacturing Process is a critical factor that determines how effectively chemical reactions occur during the production of fertilizers such as Single Super Phosphate (SSP) and other phosphorus-based fertilizers.

A well-designed reactor not only ensures optimal reaction conditions but also helps in reducing energy consumption, minimizing waste, and improving overall operational efficiency. For fertilizer manufacturers, understanding and implementing an advanced Reactor Manufacturing Process is essential for maintaining competitiveness in a rapidly growing industry.

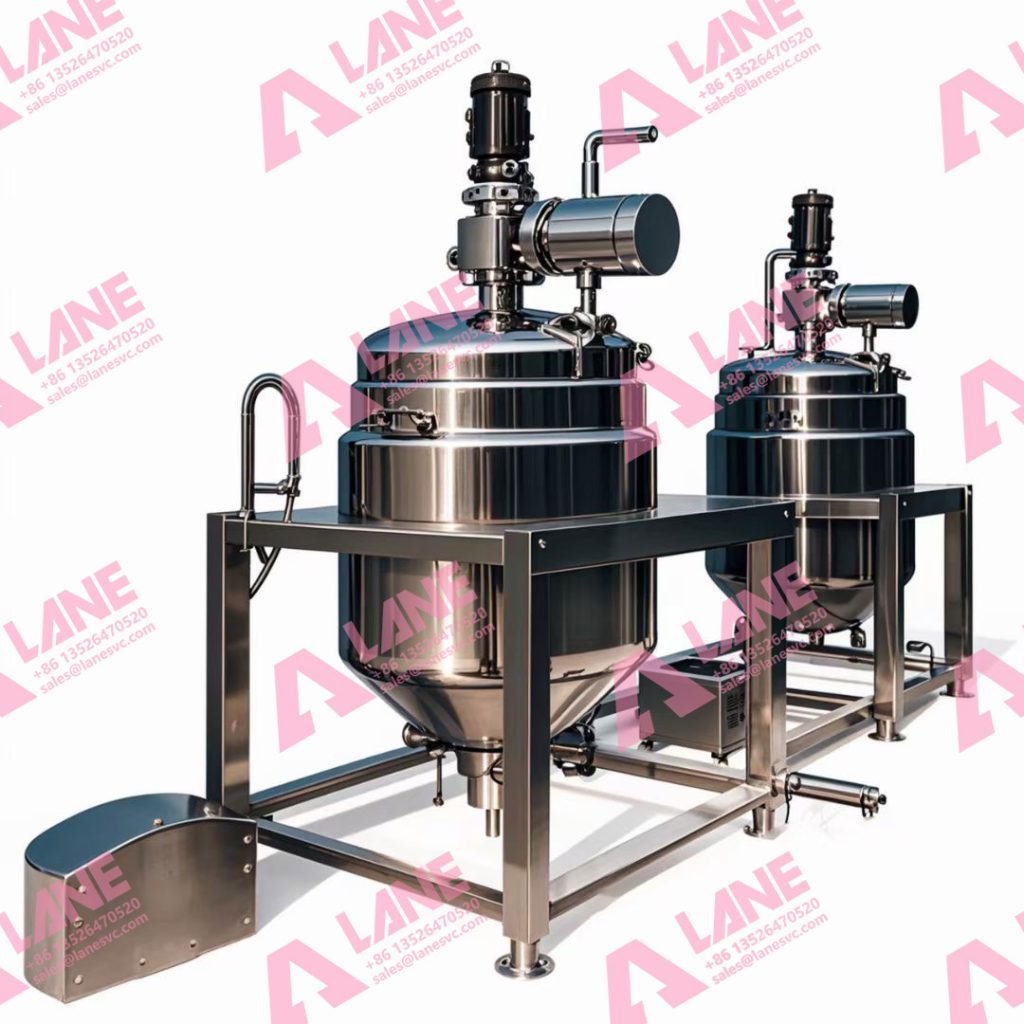

The Reactor Manufacturing Process encompasses the entire lifecycle of reactor production, from conceptual design to assembly and final testing. It involves multiple stages including material selection, structural design, precision fabrication, quality control, and instrumentation installation. Each stage is crucial to ensure that the reactor performs reliably under demanding chemical and thermal conditions commonly found in fertilizer production.

Modern reactors used in SSP production are typically designed to handle corrosive materials like phosphate rock and sulfuric acid. The manufacturing process must address challenges such as high temperature and pressure, potential abrasion, and long-term durability. A well-executed Reactor Manufacturing Process ensures that these reactors can deliver stable and uniform reactions, which directly translates into higher fertilizer efficiency.

Material Selection: One of the most critical aspects of the Reactor Manufacturing Process is choosing the right materials. Corrosion-resistant alloys, stainless steel, and specialized linings are commonly used to prevent chemical degradation over time. Proper material selection extends the reactor’s lifespan and reduces maintenance costs while maintaining consistent reaction conditions.

Structural Design: The structural design of a reactor has a direct impact on reaction efficiency. Factors such as reactor volume, shape, and mixing patterns must be optimized to ensure uniform distribution of heat and reactants. Engineers designing reactors for SSP production consider the fluid dynamics inside the vessel to prevent dead zones or uneven mixing, which can compromise product quality.

Precision Manufacturing: Precision in manufacturing is essential for achieving reliable performance. High-quality welding, accurate machining, and strict adherence to tolerances are all integral parts of the Reactor Manufacturing Process. Any deviation can affect the reactor’s pressure handling capability, temperature uniformity, or structural integrity, ultimately impacting fertilizer efficiency.

Automation and Instrumentation: Modern reactors are equipped with advanced sensors and automated control systems. Temperature, pressure, and flow rates are continuously monitored and adjusted to maintain optimal reaction conditions. Integrating automation into the Reactor Manufacturing Process not only enhances efficiency but also ensures safety and reduces human error during operations.

Quality Control: A rigorous quality control system is essential in every stage of the Reactor Manufacturing Process. This includes non-destructive testing of materials, pressure testing, dimensional verification, and performance trials. Quality assurance ensures that each reactor meets international standards and operates efficiently in real production environments.

A well-designed Reactor Manufacturing Process has a profound effect on fertilizer efficiency. First, it ensures that chemical reactions occur at optimal rates, maximizing the conversion of raw materials into usable fertilizer. In SSP production, this means higher phosphorus availability per unit of phosphate rock, resulting in a more nutrient-rich final product.

Secondly, advanced reactors reduce energy consumption. Efficient mixing and heat transfer minimize heat loss and accelerate reaction times, allowing manufacturers to produce more fertilizer with the same amount of energy. This not only reduces operational costs but also aligns with sustainable production goals.

Third, product consistency improves significantly. Uniform reactions prevent the formation of under-reacted or over-reacted particles, ensuring that each batch of fertilizer meets strict quality standards. For farmers, this translates into better crop yields and more predictable results.

Finally, well-manufactured reactors minimize waste generation. By ensuring precise reaction control, fewer raw materials are wasted, and by-products can often be recycled or repurposed, further enhancing overall production efficiency.

While a high-quality Reactor Manufacturing Process offers many benefits, several challenges must be addressed:

Fluctuating Raw Material Quality – Variations in phosphate rock or sulfuric acid can affect reaction efficiency. Solution: Design reactors with flexibility to accommodate raw material variability.

Environmental and Safety Regulations – Compliance with emission standards and safety protocols is essential. Solution: Incorporate automated monitoring and safety features in the reactor design.

Maintenance and Longevity – Corrosion, abrasion, and thermal stress can shorten reactor lifespan. Solution: Use high-quality materials, protective linings, and scheduled preventive maintenance.

Working with an experienced manufacturer ensures that these challenges are mitigated through advanced engineering, rigorous quality control, and reliable after-sales support.

Choosing the right partner for the Reactor Manufacturing Process is as important as the design itself. Experienced manufacturers like LANE Heavy Industry offer comprehensive services, from custom reactor design to installation, testing, and staff training. They ensure that the reactor not only meets technical specifications but also integrates seamlessly into the overall fertilizer production line.

By collaborating with a trusted supplier, fertilizer companies can reduce project risks, optimize production efficiency, and achieve higher returns on investment. Expertise in reactor design and manufacturing directly impacts fertilizer quality, operational safety, and long-term profitability.

The Reactor Manufacturing Process is a cornerstone of modern fertilizer production. A well-designed reactor improves chemical reaction efficiency, reduces energy consumption, ensures consistent product quality, and minimizes waste. For SSP and other phosphorus-based fertilizers, this translates into better crop yields, lower costs, and a more sustainable production process.

Investing in advanced reactor design and partnering with a reliable manufacturer allows fertilizer producers to achieve both economic and environmental benefits. Companies that adopt a high-quality Reactor Manufacturing Process are better positioned to meet growing agricultural demands while maintaining efficiency, safety, and long-term profitability.

For professional guidance, customized reactor design, and complete equipment solutions, LANE Heavy Industry offers end-to-end support, helping fertilizer manufacturers build efficient, sustainable, and high-performance production lines.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520