Release time:2026-01-05 popularity:407

Choosing the right reactor material is one of the most critical — and often underestimated — decisions in chemical and fertilizer reactor design. In real industrial projects, many performance issues, safety risks, and maintenance problems can be traced back to early-stage material selection mistakes.

This Reactor Material Selection Guide is written from a practical, engineering-oriented perspective. Instead of listing materials in theory, it focuses on common errors, real operating conditions, and how to avoid costly misjudgments when designing or purchasing chemical and fertilizer reactors.

Whether you are an equipment buyer, plant manager, or process engineer, understanding material behavior in real-world conditions will help you extend reactor life, improve safety, and control long-term costs.

In many projects, reactor material selection is driven by habit, price, or incomplete data rather than a full process evaluation. This is where problems start.

A practical Reactor Material Selection Guide must go beyond material names and focus on how materials behave under actual operating stress. Common reasons for wrong decisions include:

In fertilizer and chemical plants, reactors rarely operate under “ideal lab conditions.” Raw material impurities, feedstock variability, and cleaning chemicals all accelerate material degradation.

Stainless steel is widely used, but it is also widely misunderstood.

One of the most frequent errors addressed in any serious Reactor Material Selection Guide is assuming that “stainless steel is corrosion-resistant enough for everything.” In reality, corrosion resistance varies significantly between grades.

For example:

Without proper corrosion mapping — considering pH, temperature, reaction byproducts, and cleaning cycles — even high-grade stainless steel can suffer pitting or stress corrosion cracking within a few years.

Material selection is not only about chemical resistance. Temperature behavior matters just as much.

A reliable Reactor Material Selection Guide always evaluates:

In fertilizer reactors, frequent start-stop cycles can cause thermal fatigue. Materials with poor thermal shock resistance may develop micro-cracks that later evolve into leaks or structural failure.

This is especially relevant for reactors used in:

Chemical compatibility alone is not enough.

Many buyers follow a Reactor Material Selection Guide focused only on corrosion resistance, while ignoring mechanical wear from agitation, solid particles, or slurry flow.

In fertilizer reactors, raw materials often contain:

If the selected material lacks sufficient hardness or impact resistance, internal wear increases dramatically. This leads to thinning walls, unstable agitation, and eventually unplanned shutdowns.

A well-structured Reactor Material Selection Guide evaluates materials from multiple angles rather than relying on a single property.

Key evaluation factors include:

Chemical compatibility with raw materials and reaction byproducts

Temperature resistance under continuous and cyclic operation

Mechanical strength under pressure and agitation loads

Fabrication feasibility, including welding and forming

Maintenance and lifecycle cost, not just purchase price

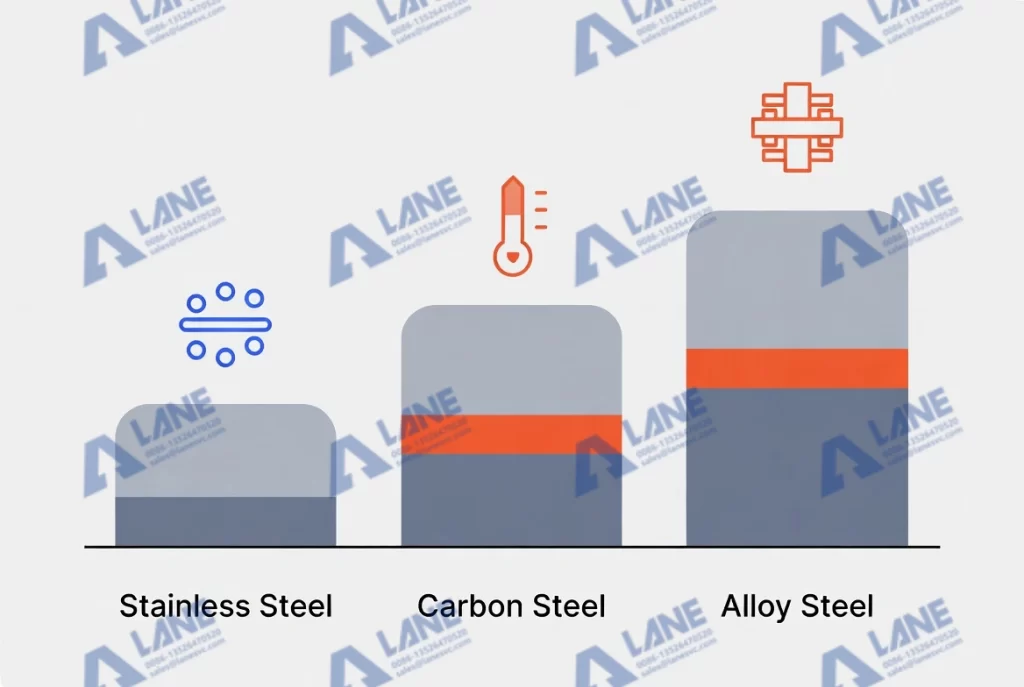

For fertilizer reactor design, materials are often selected from:

The optimal choice depends on process details, not assumptions.

Another critical lesson emphasized in this Reactor Material Selection Guide is the importance of lifecycle cost.

A lower-cost material may:

In contrast, a properly selected material may cost more initially but significantly reduce total operating cost over 10–15 years.

Experienced manufacturers always evaluate material selection from a long-term operational perspective, especially in continuous fertilizer production lines.

Based on real project experience, this Reactor Material Selection Guide recommends:

Material selection should be treated as an engineering decision, not a purchasing shortcut.

At LANE Heavy Industry Machinery Technology Co., Ltd., reactor material selection is never treated as a standard checklist.

Our engineering team applies a project-based Reactor Material Selection Guide approach, analyzing each customer’s process conditions in detail. With decades of experience in fertilizer and chemical equipment manufacturing, LANE understands how materials perform beyond theory.

We offer:

LANE reactors are designed not only to meet process requirements, but to perform consistently throughout their service life.

Q1: What is the biggest mistake in reactor material selection?

The biggest mistake is choosing materials based only on standard practice or price, without analyzing actual chemical, thermal, and mechanical conditions. A proper Reactor Material Selection Guide always starts with process analysis.

Q2: Is stainless steel always suitable for fertilizer reactors?

Not always. While stainless steel is common, certain fertilizer reactions can cause pitting or corrosion if the grade is incorrectly selected. This is why material grade evaluation is critical.

Q3: How does operating temperature affect material choice?

High temperatures and frequent thermal cycles accelerate fatigue and corrosion. Any reliable Reactor Material Selection Guide must account for long-term thermal behavior.

Q4: Can lining materials replace high-alloy metals?

In some cases, yes. Carbon steel with suitable linings can be cost-effective, but lining integrity and maintenance must be carefully managed.

Q5: Should reactor material selection be customized for each project?

Absolutely. Process conditions vary widely. Customized evaluation ensures safety, durability, and efficiency.

A well-executed Reactor Material Selection Guide can prevent years of operational problems and unnecessary costs. Material choice directly affects safety, efficiency, maintenance, and product quality in chemical and fertilizer reactor design.

By avoiding common material mistakes and working with experienced manufacturers like LANE, you can ensure your reactor system delivers stable performance and long-term value.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520