Release time:2025-11-06 popularity:407

In the world of industrial production, chemical reactors are at the heart of every chemical process. They determine how efficiently raw materials are transformed into valuable products. For anyone working in chemical engineering or process design, understanding the different reactor types in chemical engineering is essential. Each reactor type has unique advantages that influence product quality, energy efficiency, and overall production cost. In this guide, we’ll explore the most common industrial reactor types—including Glass Lined Reactor, Stainless Steel Reactor, Carbon Steel Reactor, and Liquid Reactor—and explain how to choose the right one for your process.

A chemical reactor is a vessel designed to contain and control a chemical reaction. It provides the right conditions—temperature, pressure, mixing, and catalyst contact—for reactants to transform into products efficiently. In chemical engineering, reactors come in many shapes and materials, each suited to specific reaction types. Understanding the different Reactor Types in Chemical Engineering is essential, as the reactor’s design directly affects your production yield, safety, and maintenance requirements, whether you are producing pharmaceuticals, fertilizers, or polymers. Choosing the right reactor type is not only a technical decision but also a strategic one for long-term profitability.

A Glass Lined Reactor combines the strength of a steel shell with the corrosion resistance of a glass coating. This structure makes it ideal for chemical processes involving strong acids, alkalis, or highly reactive compounds. The glass lining provides a smooth, non-stick surface that prevents material buildup and makes cleaning easy. Common applications include pharmaceutical synthesis, fine chemical production, and food-grade processing. Key advantages:

For industries that handle aggressive chemicals, glass lined reactors are a top choice due to their safety and reliability.

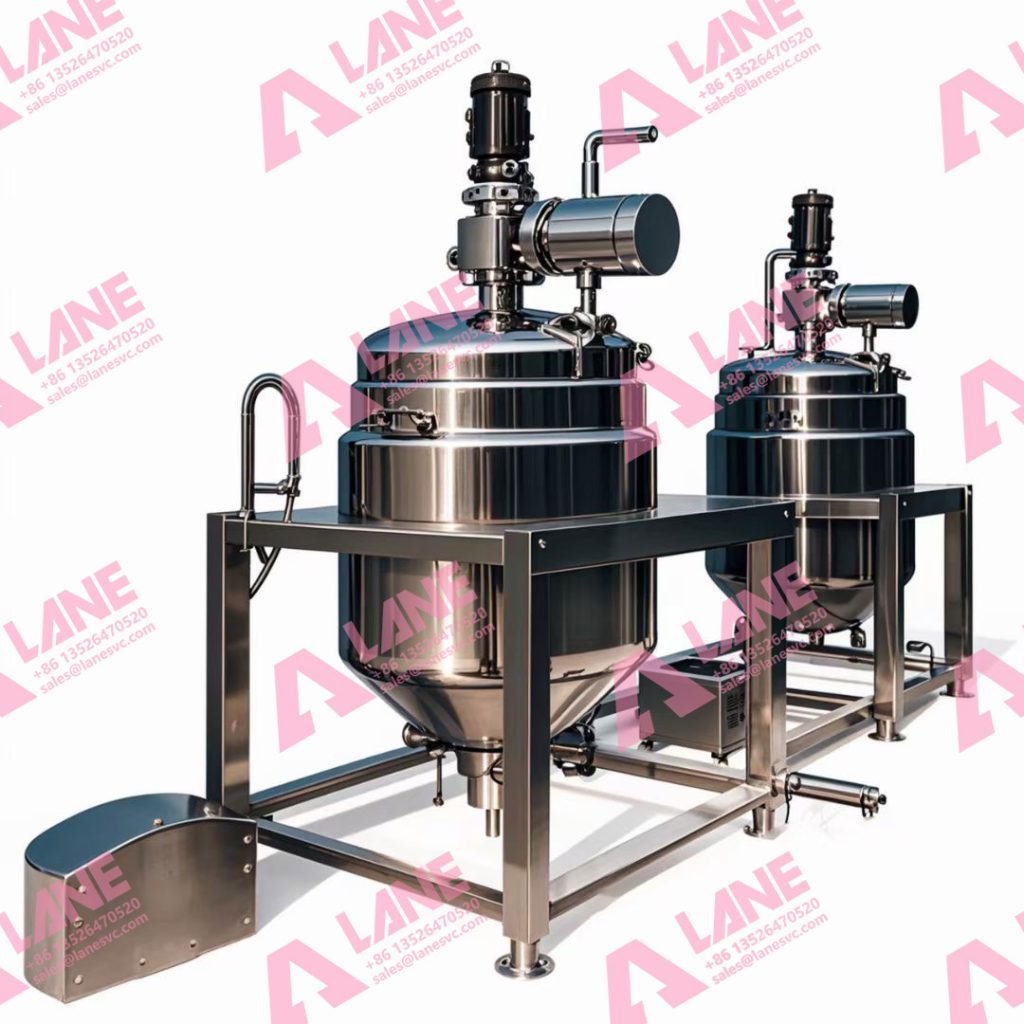

Stainless Steel Reactors are built using high-quality stainless steel, typically grade 304 or 316, known for its resistance to oxidation and high temperatures. They are among the most widely used Reactor Types in Chemical Engineering and petrochemical industries. These reactors can withstand high pressure and are suitable for reactions involving gases, polymers, and biological materials. Their durability and hygiene make them popular in food, pharmaceutical, and biotechnology plants. Key advantages:

A stainless-steel reactor is the preferred choice when your process demands both cleanliness and structural integrity under extreme conditions.

A Carbon Steel Reactor is valued for its robustness and cost-effectiveness. It’s typically used in large-scale industrial plants that work with non-corrosive or mildly reactive materials. Although it lacks the corrosion resistance of stainless or glass lined designs, carbon steel provides excellent structural strength, making it suitable for applications like fertilizer production, oil refining, and petrochemical processing. Key advantages:

When the process conditions are stable and non-corrosive, carbon steel reactors offer excellent performance at an economical price.

Liquid Reactors are designed for liquid-phase or homogeneous reactions. They are widely used in industries such as fertilizers, dyes, coatings, and resins. These reactors provide efficient heat transfer and mixing, ensuring uniform reactions throughout the liquid medium. They represent one of the specialized Reactor Types in Chemical Engineering that are easy to operate and suitable for continuous or batch production. Key advantages:

For processes involving liquid reactants or solutions, a liquid reactor ensures stability, high conversion efficiency, and consistent product quality.

Selecting the right Reactor Types in Chemical Engineering depends on several important factors:

Reaction type: acid-base, high-pressure, polymerization, etc.

Material corrosiveness: choose glass lined for highly corrosive chemicals.

Production scale: stainless or carbon steel reactors for large-volume manufacturing.

Budget and maintenance needs: balance performance with long-term cost.

Example decisions regarding different Reactor Types in Chemical Engineering:

Understanding these differences helps engineers make smarter investment and design decisions.

Each reactor type serves distinct purposes across industries:

Glass Lined Reactors: used in pharmaceuticals, agrochemicals, and high-purity chemicals.

Stainless Steel Reactors: applied in petrochemical, polymer, and food processing.

Carbon Steel Reactors: essential in fertilizer and bulk chemical manufacturing.

Liquid Reactors: used in resin, paint, and fertilizer production lines.

The diversity of Reactor Types in Chemical Engineering allows manufacturers to tailor their equipment to specific reactions, improving efficiency and quality across the production process.

Henan LANE Heavy Industry Machinery Technology Co., Ltd. specializes in designing and manufacturing advanced reactors for industrial applications. Understanding the different Reactor Types in Chemical Engineering is crucial, and our product range includes Glass Lined Reactors, Stainless Steel Reactors, Carbon Steel Reactors, and Liquid Reactors, all engineered to meet diverse chemical process requirements.

With modern production technology, strict quality control, and professional after-sales service, LANE provides reliable reactor solutions that help you increase productivity while reducing operational risks. We are experts in matching our equipment to your specific process needs, offering guidance on various Reactor Types in Chemical Engineering to ensure optimal performance.

Whether you’re upgrading your current system or starting a new project, our experts can help you select the ideal reactor for your specific needs.

Understanding the various reactor types in chemical engineering is essential for anyone involved in chemical production and process design. Each reactor—glass lined, stainless steel, carbon steel, or liquid—offers unique benefits suited to different applications. By choosing the right equipment and trusted manufacturer, you can enhance your production efficiency, product quality, and long-term profitability. Contact LANE Heavy Industry today to explore our full range of reactor solutions and take your chemical production line to the next level.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520