Release time:2025-12-08 popularity:407

In modern agriculture, liquid fertilizers play an increasingly critical role in improving crop yields, enhancing soil health, and supporting sustainable farming practices. For farmers and fertilizer manufacturers alike, the efficiency and reliability of the production process are paramount. This is where stainless steel reactor equipment for liquid fertilizer production becomes an indispensable asset. Unlike traditional production methods, stainless steel reactors offer precision, durability, and ease of operation, making them the go-to choice for high-quality liquid fertilizer manufacturing.

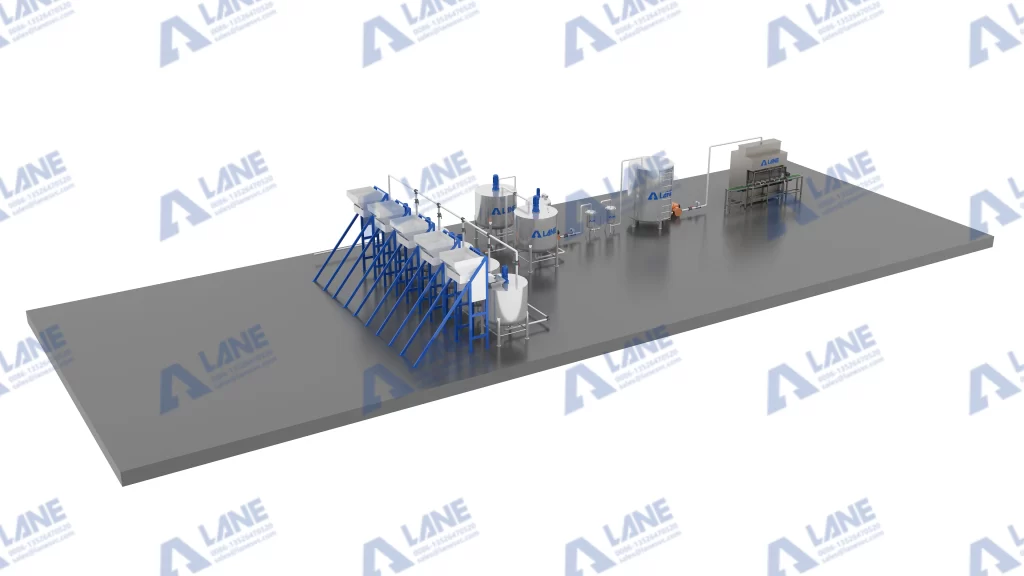

The first time I visited a liquid fertilizer plant, I was immediately struck by the clean and organized environment. The reactors, made entirely of stainless steel, gleamed under the factory lights, and every stage of production seemed to flow seamlessly. What stood out most was how the equipment facilitated consistent mixing, heating, and chemical reactions—ensuring that the final fertilizer product maintained uniform nutrient content. Over time, I have come to realize that the choice of reactor equipment can make or break a fertilizer production operation.

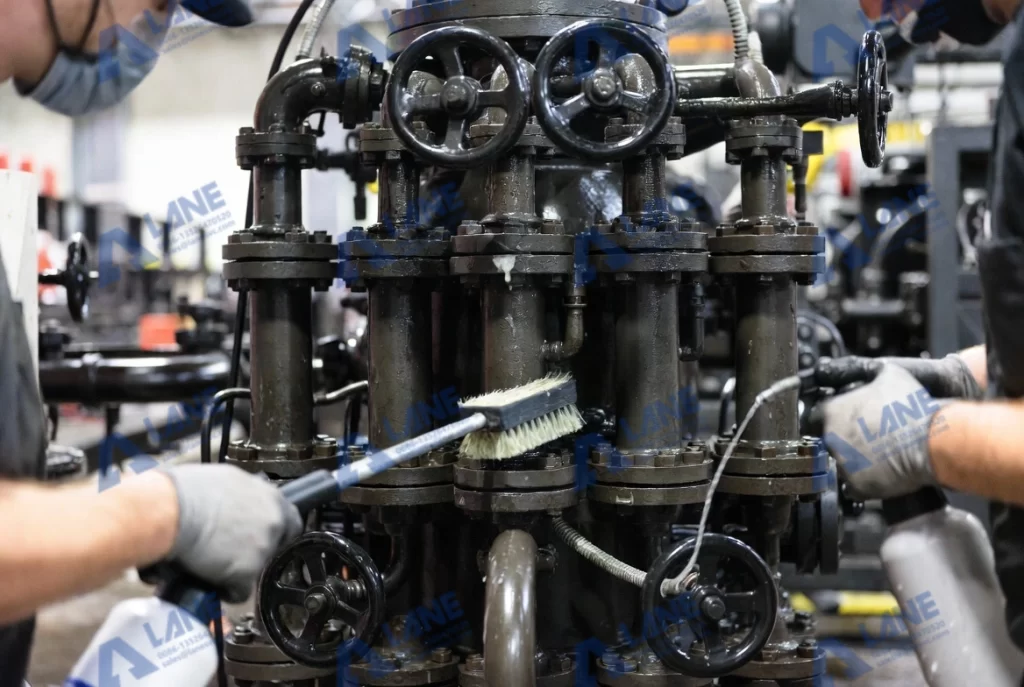

One of the key advantages of stainless steel reactor equipment for liquid fertilizer production is its resistance to corrosion. Liquid fertilizers often contain strong chemical agents that can damage ordinary metal vessels, reducing their lifespan and potentially contaminating the product. Stainless steel reactors, however, withstand these harsh environments while maintaining structural integrity. This means manufacturers can run production cycles more efficiently, reduce downtime, and minimize the need for frequent repairs or replacements.

Another benefit is precise temperature and mixing control. Liquid fertilizer production involves complex chemical reactions that require strict adherence to temperature, pH, and mixing speed. Stainless steel reactor equipment for liquid fertilizer production is typically equipped with advanced heating and cooling systems, along with automated mixers, allowing operators to maintain optimal conditions throughout the process. This not only improves nutrient consistency but also ensures that each batch meets regulatory and quality standards.

Durability and long-term cost savings are additional factors that make stainless steel reactor equipment for liquid fertilizer production highly desirable. Although the initial investment may be higher than that of other reactor types, the reduced maintenance, fewer breakdowns, and longer operational lifespan more than compensate over time. For manufacturers planning to scale their operations, this translates into a more predictable production schedule and lower overall operational risk.

Maintenance and ease of cleaning are also notable advantages. In liquid fertilizer production, hygiene is critical to prevent microbial contamination and maintain product stability. Stainless steel reactor equipment for liquid fertilizer production features smooth, non-porous surfaces that resist chemical residues, simplifying cleaning and sterilization. Operators can perform routine maintenance without extensive downtime, keeping the production line running smoothly.

Moreover, the flexibility of stainless steel reactor equipment makes it suitable for various liquid fertilizer formulations. From NPK solutions to micronutrient-enriched blends, these reactors can handle diverse chemical compositions while maintaining product quality. This versatility is particularly valuable for manufacturers serving multiple markets or customizing formulations for different crops and soil types.

1. What types of fertilizers can be produced using stainless steel reactors?

These reactors can produce a wide range of liquid fertilizers, including NPK solutions, single-nutrient fertilizers, and specialty micronutrient formulations.

2. How long does a typical production cycle take?

The cycle length depends on the formulation and reactor size, but stainless steel reactors allow for efficient chemical reactions, often reducing production time compared to traditional vessels.

3. How do stainless steel reactors improve product quality?

By providing precise temperature, mixing, and chemical control, stainless steel reactors ensure uniform nutrient distribution and minimize the risk of contamination.

4. Is specialized training required to operate these reactors?

Most reactors come with user-friendly controls and automated systems, but operators should be trained on safety protocols and proper maintenance to ensure optimal performance.

5. Can these reactors be integrated into existing production lines?

Yes, stainless steel reactor equipment for liquid fertilizer production can often be customized and integrated into existing setups to improve efficiency and output.

LANE (Henan LANE Heavy Industry Machinery Technology Co., Ltd.) is a global leader in fertilizer production equipment, specializing in stainless steel reactor equipment for liquid fertilizer production and complete fertilizer production lines. With over 120 international installations, ISO certification, and a strong R&D team, LANE provides reliable, durable, and customizable solutions for farms, fertilizer factories, and industrial applications. The company supports third-party factory inspections, offers overseas installation services, and ensures a five-year warranty, helping customers turn waste or raw materials into high-quality liquid fertilizers efficiently and sustainably.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520