Release time:2025-11-13 popularity:407

In the evolving fertilizer industry, production efficiency and material durability are key to maintaining competitiveness. A stainless steel reactor for fertilizer production is an essential piece of equipment that enables precise chemical reactions under controlled conditions, ensuring stability and reliability in continuous operation. With its excellent corrosion resistance, long service life, and compatibility with a wide range of fertilizer formulations, a stainless steel reactor for fertilizer production has become indispensable in both organic and chemical fertilizer manufacturing.

This guide explores the structure, advantages, selection process, and maintenance practices of stainless steel reactors to help fertilizer manufacturers achieve higher productivity, consistent product quality, and safer long-term operation.

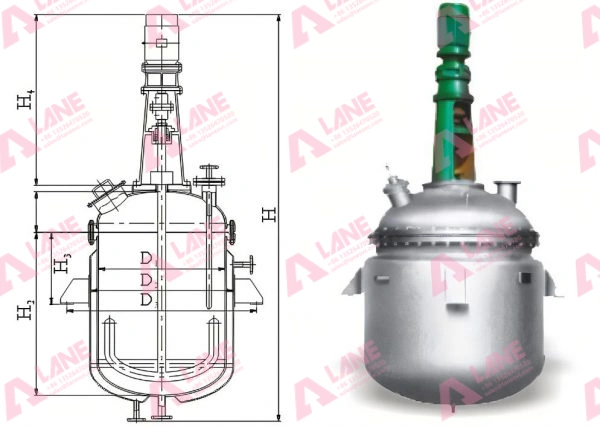

A stainless steel reactor is a vessel designed for chemical reactions such as synthesis, mixing, and neutralization during fertilizer production. It consists of several key components, including a main reactor body, jacket or coil for heating and cooling, a mechanical agitator, temperature control system, and pressure gauge.

Unlike carbon steel or glass-lined reactors, stainless steel models offer superior resistance to acids, alkalis, and chlorides commonly found in fertilizer formulations. This durability ensures consistent operation and minimizes contamination, making them ideal for producing high-quality compound and liquid fertilizers.

The stainless steel reactor for fertilizer production provides several technical and operational benefits:

Excellent Corrosion Resistance – Stainless steel can withstand strong acids and salts, ensuring durability in harsh fertilizer environments.

Superior Heat Transfer – It allows precise temperature control for optimal reaction conditions.

Easy Cleaning and Maintenance – The smooth inner surface prevents residue buildup and supports hygienic operations.

Automation Compatibility – Modern reactors can integrate with sensors, PLCs, and smart systems for real-time process monitoring.

Sustainability and Energy Efficiency – High thermal efficiency reduces energy consumption and waste.

These advantages make stainless steel reactors a preferred choice for sustainable and large-scale fertilizer production plants.

A stainless steel reactor permits chemical reactions under regulated temperature, pressure, and agitation in the production of fertilizer. When raw materials are added to the vessel, the appropriate reaction conditions are maintained by heating or cooling systems. Uniform mixing is ensured by the agitator, enabling full reaction and constant fertilizer quality.

Such reactors are frequently used in operations where exact control directly affects yield and product stability, such as the synthesis of urea solutions, the manufacturing of NPK compounds, and the blending of liquid fertilizer.

There are several types of stainless steel reactors used across the fertilizer industry:

LANE Heavy Industry offers a full range of stainless steel reactors for fertilizer production, each engineered for efficiency, safety, and compliance with international standards.

Choosing the appropriate reactor involves several key considerations:

Fertilizer Type: The composition of raw materials—organic, phosphate, or compound—determines the required material and design.

Production Scale: The reactor capacity should align with the desired output and future expansion needs.

Temperature and Pressure Requirements: Select models rated for specific reaction conditions to ensure performance and safety.

Manufacturer Reliability: Partnering with a trusted manufacturer such as LANE Heavy Industry ensures quality, certification, and long-term technical support.

Selecting the right stainless steel reactor for fertilizer production guarantees process stability, minimizes downtime, and reduces operational costs.

Regular maintenance extends the reactor’s life and enhances operational safety.

Stainless steel’s resistance to corrosion and high temperatures reduces maintenance frequency and supports continuous production efficiency.

A stainless steel reactor for fertilizer production plays a vital role in advancing sustainable and efficient manufacturing practices across the fertilizer industry. Its superior corrosion resistance, efficient heat transfer, and precise temperature control minimize energy loss during chemical reactions, resulting in higher productivity and lower operational costs. The advanced control systems integrated within these reactors also reduce chemical waste and emissions, helping manufacturers meet increasingly strict environmental regulations.

Moreover, the inherent recyclability and long service life of stainless steel contribute to a lower overall environmental footprint. When a stainless steel reactor for fertilizer production is combined with intelligent automation, energy-efficient motors, and clean-energy integration, fertilizer plants can achieve greener, safer, and more cost-effective operations—paving the way for a more sustainable global agriculture system.

Q1: What makes stainless steel reactors better for fertilizer production?

They offer superior corrosion resistance, longer life, and better thermal efficiency than traditional materials, ensuring reliable and clean chemical processing.

Q2: Can stainless steel reactors handle all fertilizer types?

Yes. They are suitable for producing organic, phosphate, and NPK compound fertilizers.

Q3: How long does a stainless steel reactor last?

With proper maintenance, a high-quality stainless steel reactor can last over 15–20 years.

Q4: Are these reactors compatible with automation?

Absolutely. Modern stainless steel reactors integrate seamlessly with digital control systems for precision monitoring and performance optimization.

Q5: Where can I find a reliable manufacturer?

LANE Heavy Industry is a professional supplier of stainless steel reactors for fertilizer production, offering custom solutions, full installation, and global service support.

A stainless steel reactor for fertilizer production represents a key advancement in modern agricultural manufacturing. Its durability, precision, and adaptability make it an essential component of efficient and sustainable fertilizer plants, ensuring optimal reaction control and high production efficiency.

By partnering with trusted manufacturers like LANE Heavy Industry, fertilizer producers can achieve stable operations, superior product quality, and long-term economic benefits. Through continuous innovation in stainless steel reactor for fertilizer production technology, LANE supports global agriculture with reliable equipment and integrated fertilizer production solutions.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520