Release time:2025-11-10 popularity:407

Efficiency, dependability, and safety are critical concerns for chemical, pharmaceutical, fertilizer, and food processing facilities in today’s cutthroat industrial environment. The stainless steel reactor, a vital piece of machinery that guarantees accurate chemical reactions and constant product quality, is at the center of many of these manufacturing systems. Therefore, selecting the best Stainless Steel Reactor Manufacturer is crucial and can have a direct impact on the long-term success, operational expenses, and performance of your facility.

A professional manufacturer offers more than simply a piece of equipment; they also offer engineering know-how, design optimization, and after-sales assistance customized to your unique process needs. This article will discuss what constitutes a trustworthy manufacturer of stainless steel reactors, what aspects to take into account before making a purchase, and how the correct collaboration may improve your production’s sustainability and efficiency.

In order to turn unfinished design thoughts into fully operational, high-performance industrial reactors, a Stainless Steel Reactor Manufacturer is essential. Beyond manufacturing, a Stainless Steel Reactor Manufacturer guarantees that every reactor satisfies stringent quality requirements, including material selection, precise welding, and pressure testing.

A trustworthy manufacturer is aware that different reactor configurations are needed for every business. Reactors used in chemical synthesis, for instance, need to be able to handle strong acids and bases, whilst those used in food processing or fertilizer need to be extremely hygienic and resistant to corrosion. A professional manufacturer assists customers in achieving maximum efficiency, product consistency, and safety assurance by providing tailored solutions, technical guidance, and compliance with international standards like ASME or CE.

You may find a reliable Stainless Steel Reactor Manufacturer for your project by considering a number of important elements.

The materials employed in a reactor have a significant impact on its performance and longevity. Excellent resistance to corrosion, pressure, and temperature variations is offered by premium stainless steel, such as 304, 316L, or duplex grades. Strict inspection reports, material certifications, and adherence to global manufacturing standards are all guaranteed by a competent manufacturer.

Industrial processes are not all the same. Customized stainless steel reactor designs that fit your unique reaction type, capacity, heating technique, and pressure requirements should be available from a reputable manufacturer. To maximize design correctness and guarantee safe, effective functioning under a variety of operating situations, modern manufacturers employ sophisticated CAD and simulation technologies.

Experience is important. A skilled manufacturer of stainless steel reactors can provide insightful advice on process optimization and safety enhancements. They can suggest the ideal reactor configuration to meet your needs because they are aware of the difficulties encountered in many industries, such as high-viscosity materials in the creation of polymers or corrosion issues in the processing of chemical fertilizers.

Strict quality control procedures are used throughout the whole production process by reputable manufacturers. Every stage, from raw material inspection to pressure and vacuum testing, needs to be closely watched. Quality control ensures that long-term operational safety and performance goals are met by the finished reactor.

Buying a reactor is a continuous process. The availability of spare parts, installation advice, and ongoing technical assistance are all essential components of a manufacturer’s service. For overseas clients, a trustworthy provider will offer lifelong technical support and prompt response times, which will minimize downtime and increase equipment longevity.

Long-term advantages of working with a reputable stainless steel reactor manufacturer extend well beyond the first equipment delivery.

A dependable manufacturer becomes more than simply a supplier; they become your long-term technical partner, assisting you in achieving sustainable growth, operational dependability, and constant product quality.

Stainless steel reactors are appropriate for a variety of industrial industries due to their versatility:

The significance of choosing the best stainless steel reactor manufacturer is further highlighted by the fact that each of these industries depends on precisely designed reactors to achieve consistency, safety, and regulatory compliance.

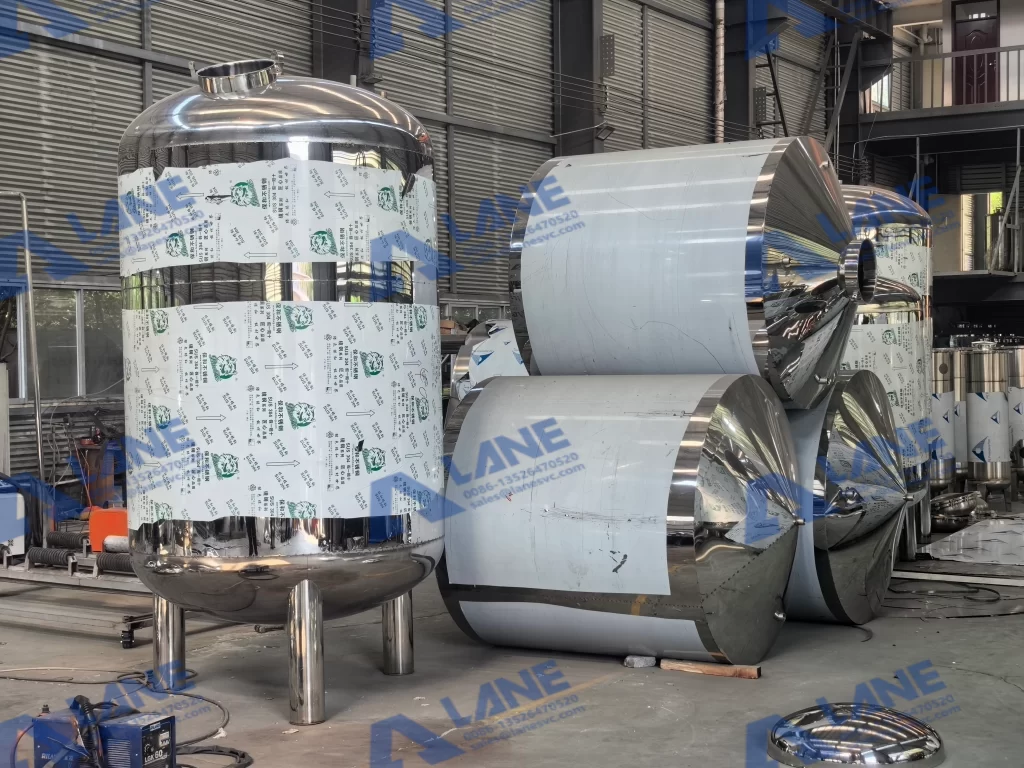

LANE Heavy Industry Machinery Technology Co., Ltd. is a top manufacturer of stainless steel reactors in China, offering cutting-edge solutions to customers throughout the world. The company has years of manufacturing experience and great technical competence.

To ensure optimal durability and process efficiency, our stainless steel reactors are constructed using high-quality materials, stringent welding standards, and cutting-edge design technologies. Additionally, LANE provides full engineering services, including design, customization, on-site installation, and post-purchase assistance. LANE offers dependable, affordable, and environmentally friendly reactor systems that are customized to meet your demands, whether you are building a new plant or modernizing an existing production line.

One of the most crucial aspects in starting a profitable industrial enterprise is selecting the best Stainless Steel Reactor Manufacturer for your production needs. A skilled Stainless Steel Reactor Manufacturer guarantees that your equipment satisfies the highest requirements for efficiency, safety, and dependability while offering the flexibility to adjust to changing production demands. You may lower operational risks, gain long-term performance consistency, and keep a competitive edge in your sector by working with a reliable supplier like LANE.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520