Release time:2025-12-10 popularity:407

Water is one of the most critical resources for industrial operations, and managing wastewater efficiently is essential for environmental compliance, operational safety, and cost control. Among the technologies used in wastewater management, the Wastewater Treatment System plays a central role in ensuring that harmful pollutants are removed before discharge or reuse. For modern plants, understanding how this equipment works, its design considerations, and the benefits it provides is key to achieving sustainable operations.

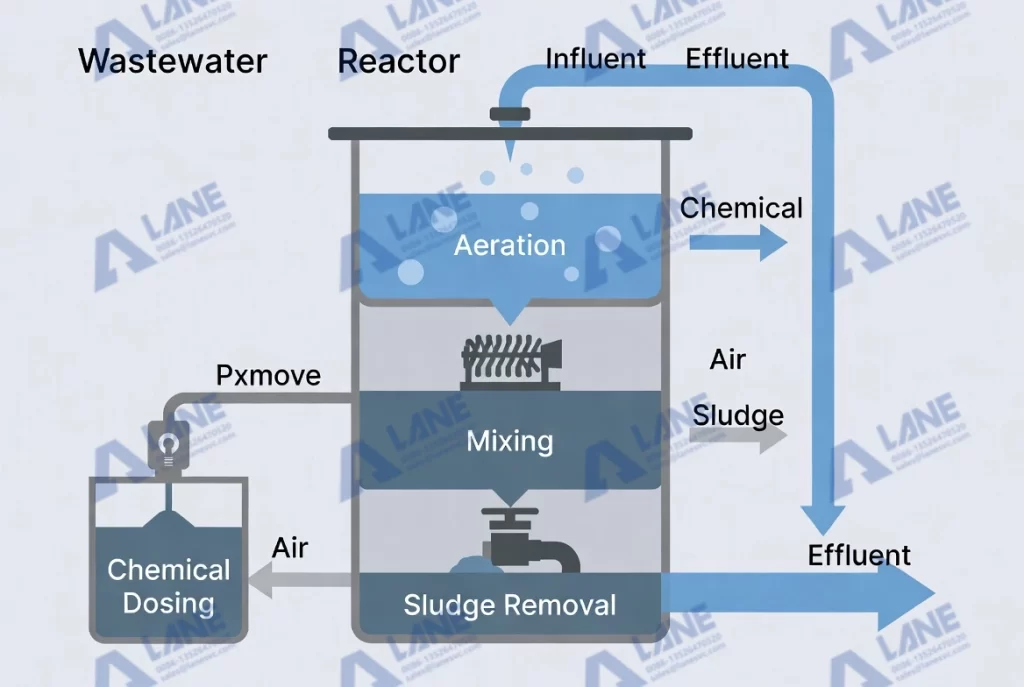

A waste water treatment reactor is designed to process industrial or municipal wastewater by facilitating physical, chemical, or biological reactions that break down contaminants. Unlike traditional settling tanks or filtration systems, a reactor actively treats wastewater, often combining aeration, mixing, chemical dosing, and biofilm growth in a single, controlled environment. This integrated approach ensures higher treatment efficiency, reduces treatment time, and minimizes sludge production.

The demand for cleaner production and stricter environmental regulations has made Wastewater Treatment System increasingly important. Traditional methods are often insufficient for handling complex industrial effluents that contain high levels of organic matter, heavy metals, or chemicals. Here are the main reasons plants now prefer reactor-based treatment:

Higher Treatment Efficiency

By combining aeration, mixing, and controlled chemical reactions, a waste water treatment reactor ensures that contaminants are broken down more thoroughly than in conventional systems.

Space Optimization

Reactors are often compact, allowing plants to manage large volumes of wastewater in a smaller footprint—a critical factor for facilities with limited space.

Flexibility with Wastewater Composition

Modern reactors can be customized to handle varying concentrations of pollutants, pH levels, and organic loads. This adaptability reduces the risk of process failure.

Reduced Operating Costs

Efficient reactors lower energy usage and minimize sludge disposal costs, making them a cost-effective long-term investment.

A well-designed Wastewater Treatment System typically includes:

Each component can be tailored to meet specific wastewater characteristics, making the reactor highly versatile and suitable for industrial, municipal, or combined applications.

As a global manufacturer specializing in environmental and industrial machinery, LANE (Henan LANE Heavy Industry Machinery Technology Co., Ltd.) has helped plants in over 200 countries improve wastewater management through customized waste water treatment reactors. Unlike standard equipment, LANE focuses on tailoring solutions to match the unique composition of each client’s effluent, plant layout, and treatment goals.

LANE engineers start by evaluating:

Based on these factors, LANE designs a complete waste water treatment reactor system, including layout plans, optimized chemical dosing, aeration strategies, and control automation. The company’s ISO certification, technical expertise, and long-term experience in environmental machinery ensure that each reactor operates reliably and efficiently in real-world conditions.

Plants that adopt Wastewater Treatment System often see measurable improvements within months:

Many plant managers describe investing in a Wastewater Treatment System as a solution that pays for itself, thanks to reduced fines, lower operating costs, and improved sustainability credentials.

1. Is a waste water treatment reactor only suitable for large plants?

No. Reactors are scalable and can be adapted for small, medium, and large facilities, making them versatile across industries.

2. How long does it take to install a custom waste water treatment reactor?

Installation time depends on plant size and reactor complexity but generally ranges from 30 to 90 days, including design, fabrication, and commissioning.

3. Can a waste water treatment reactor handle highly variable wastewater?

Yes. Modern reactors are designed to adapt to fluctuations in flow, pH, and pollutant concentrations, ensuring consistent treatment.

4. Does reactor-based treatment reduce environmental impact?

Absolutely. By efficiently removing organic matter, heavy metals, and pathogens, reactors minimize pollution and support sustainable water management.

5. What differentiates LANE’s reactors from standard options?

LANE integrates advanced engineering design, real-world testing, and international standards to provide reactors that perform reliably under operational conditions, not just in theory.

For plants seeking operational stability, regulatory compliance, and long-term cost efficiency, investing in a Wastewater Treatment System is no longer optional—it’s essential. Modern reactors not only improve treatment efficiency but also reduce energy usage, operational risks, and environmental impact. Whether upgrading existing infrastructure or building a new plant, choosing a tailored waste water treatment reactor ensures that every step of wastewater management—from influent handling to effluent discharge—is optimized for reliability and performance.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520